Incremental Sheet Metal Forming Simulation

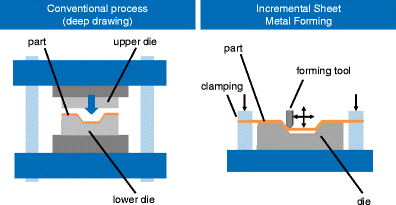

In conventional forming process the products are produced by dedicated tools i e.

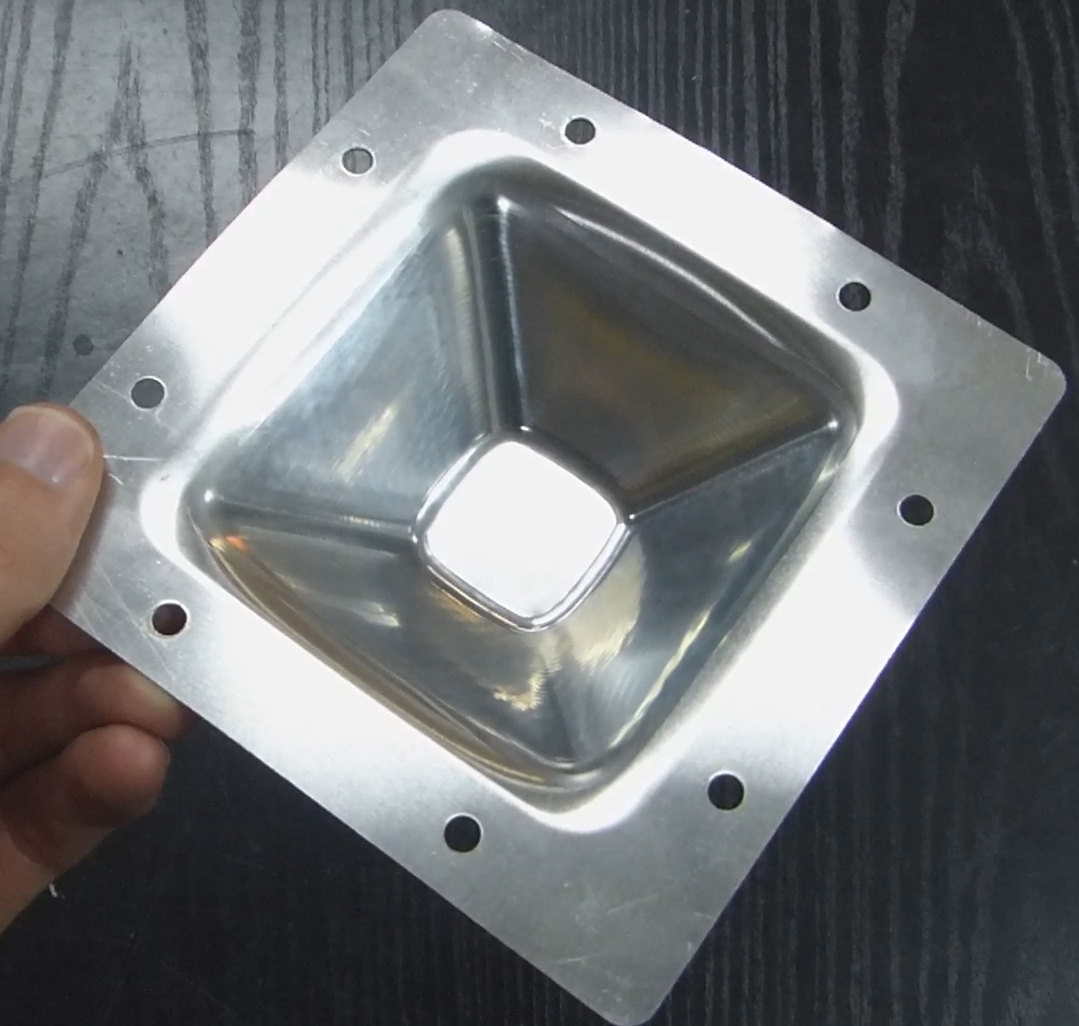

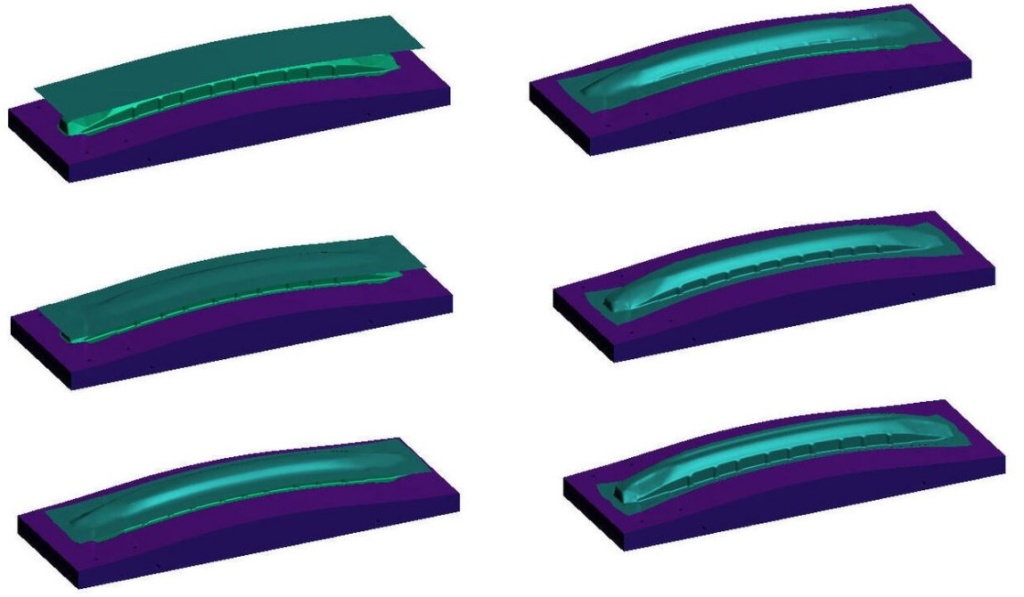

Incremental sheet metal forming simulation. The dimple was drawn and through our simulation we were able to successfully reduce the process to six steps in order to minimize the thinning percentage to the required level. Simulation of single point incremental forming spif in catia v5. It is important to understand the difference between the two calculation methods and to understand when it is appropriate to use each method. This video will show you how to perform simulation of single point incremental forming spif in catia v5.

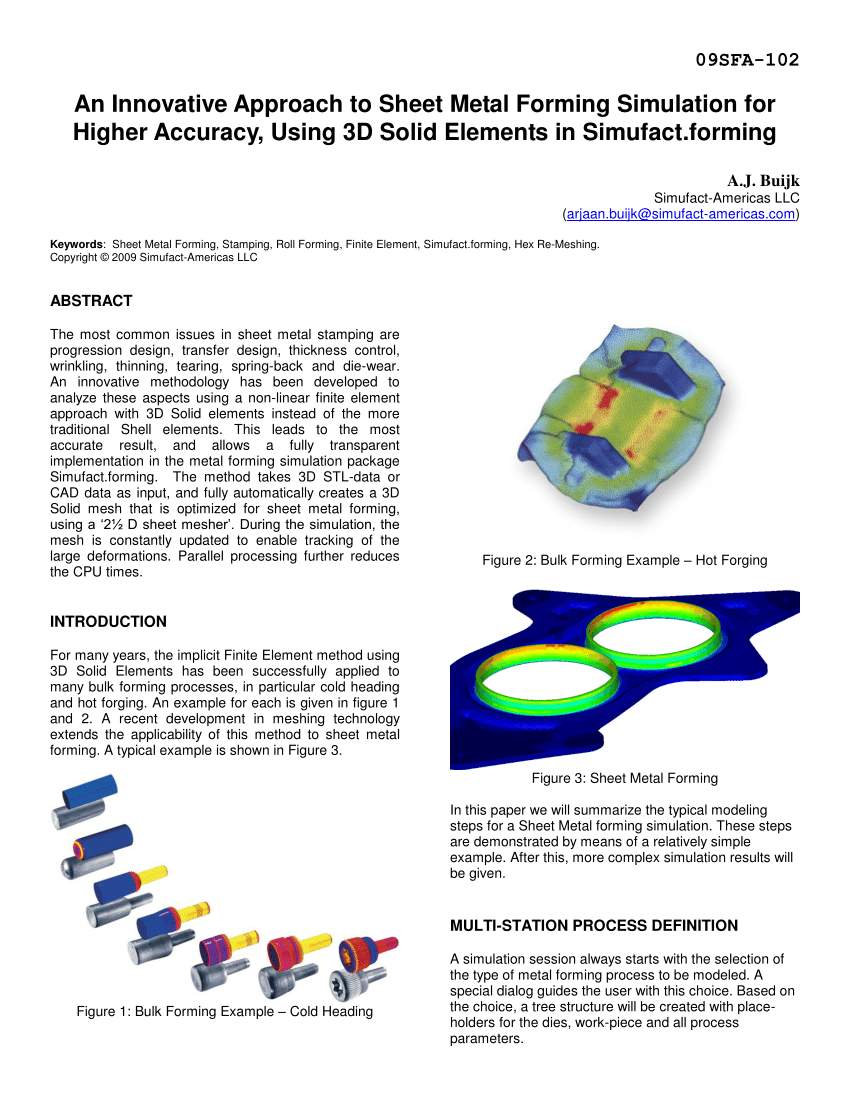

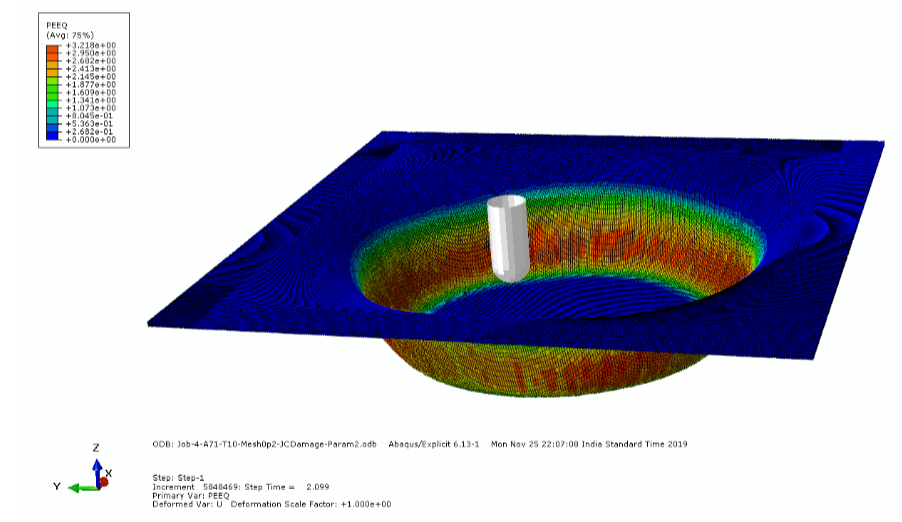

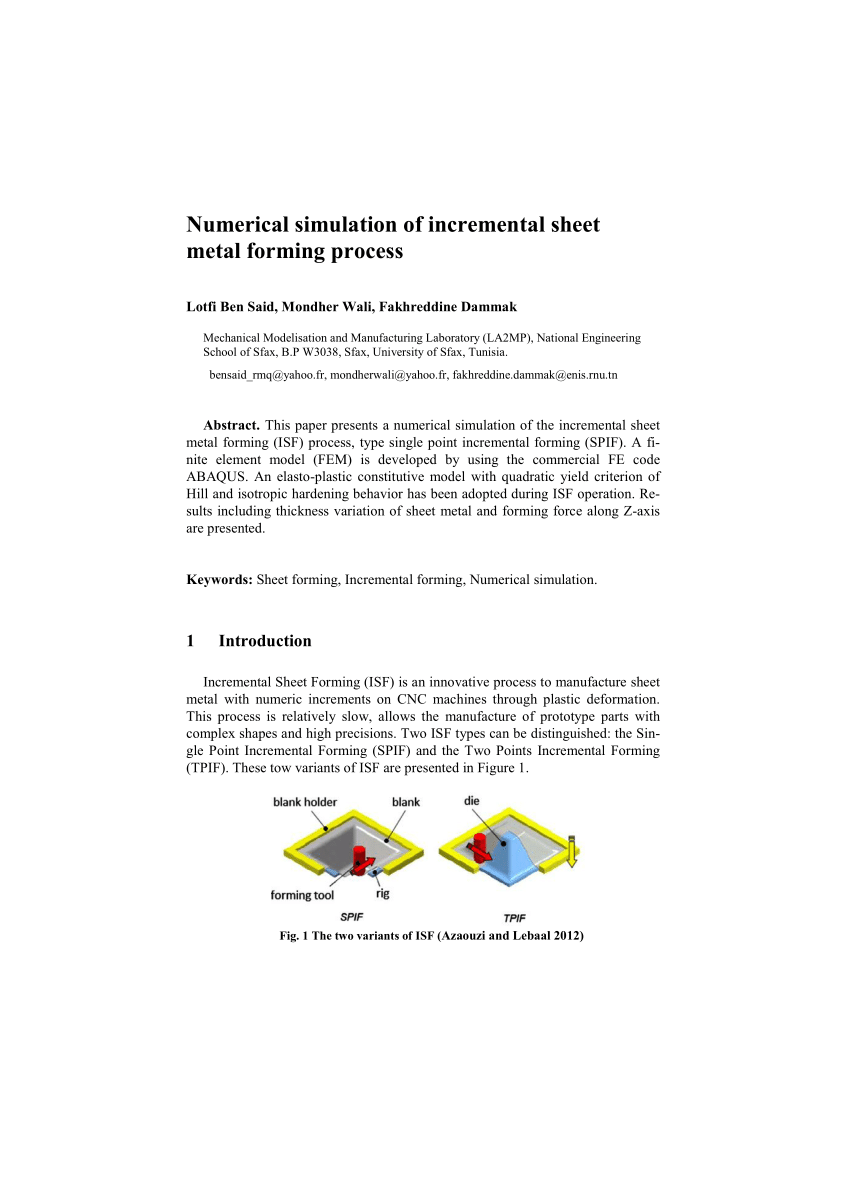

Two broad divisions in the application of finite element analysis method for sheet metal forming can be identified as inverse one step and incremental. In the present paper deformation behavior of sheet metal in an incremental forming process is numerically simulated using a dynamic explicit finite element code dyna3d halliquist 1989. In incremental simulations the forming process is divided into steps or increments and the problem is solved incrementally through time. In metal forming simulation the forming of sheet metal is simulated on the computer with the help of special software.

Incremental sheet forming isf process is an advanced flexible manufacturing process to produce complex 3d products. 13 3 3 incremental forming analysis. Enjoy the videos and music you love upload original content and share it all with friends family and the world on youtube. Hence with these methods it is possible to optimize the tool as well as the component.

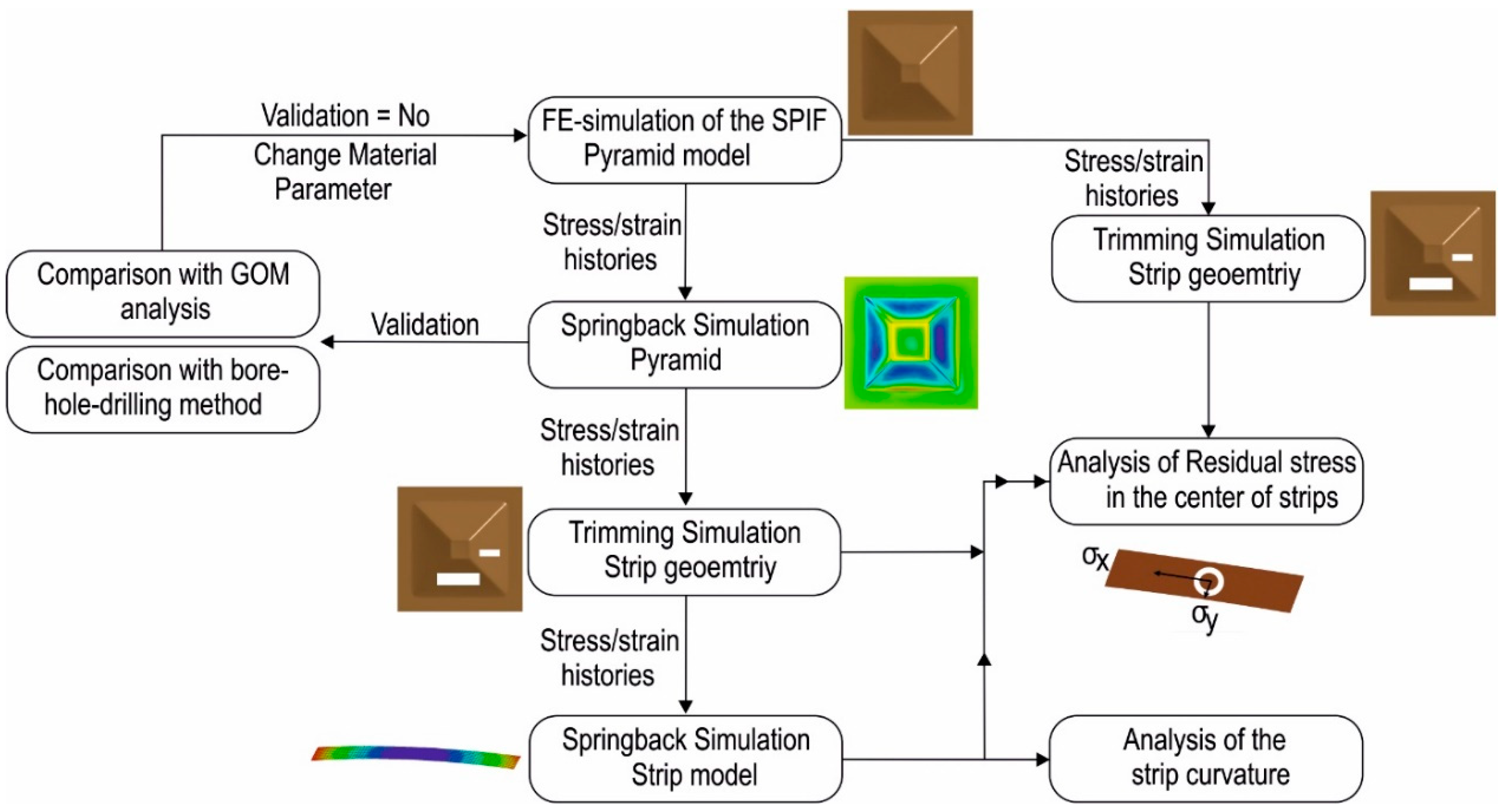

Incremental simulations yield all the relevant parameters that interest the forming expert from strain distribution sheet thickness and cracks for example to springback in the trimmed part stress distribution and hardening. One step a single step calculation that completes very quickly in one step. However isf does not require any dedicated tool. Simulation makes it possible to detect errors and problems such as wrinkles or splits in parts on the computer at an early stage in forming.

Unlike one step simulation in which only the final part shape is solved incremental forming simulation allows the accurate modeling of sheet forming processes. Because this is a dynamic code mass of the material and the deformation speed affect the deformation behavior. The forming process simulations were successful in eliminating forming problems splits wrinkles and other negative outcomes before the tooling was designed and manufactured.