How To Cut Sheet Metal With Clean Edge

In addition special sheet metal cutting tips are available for specific metals and thicknesses.

How to cut sheet metal with clean edge. Mark your line and clamp a 2 4 or even a yardstick parallel to the edge use the torch head to get the proper spacing and then you have an easy guide to get a clean straight cut. The illustrations are for a small bracket but i have cut 3 foot. Use a die grinder with the mounted point and simply run the point over the edge of the sheet metal. Cutting corrugated metal with anything producing heat can void the warranty by your manufactures and can make permanent damage to the metal sheets causing them to rust.

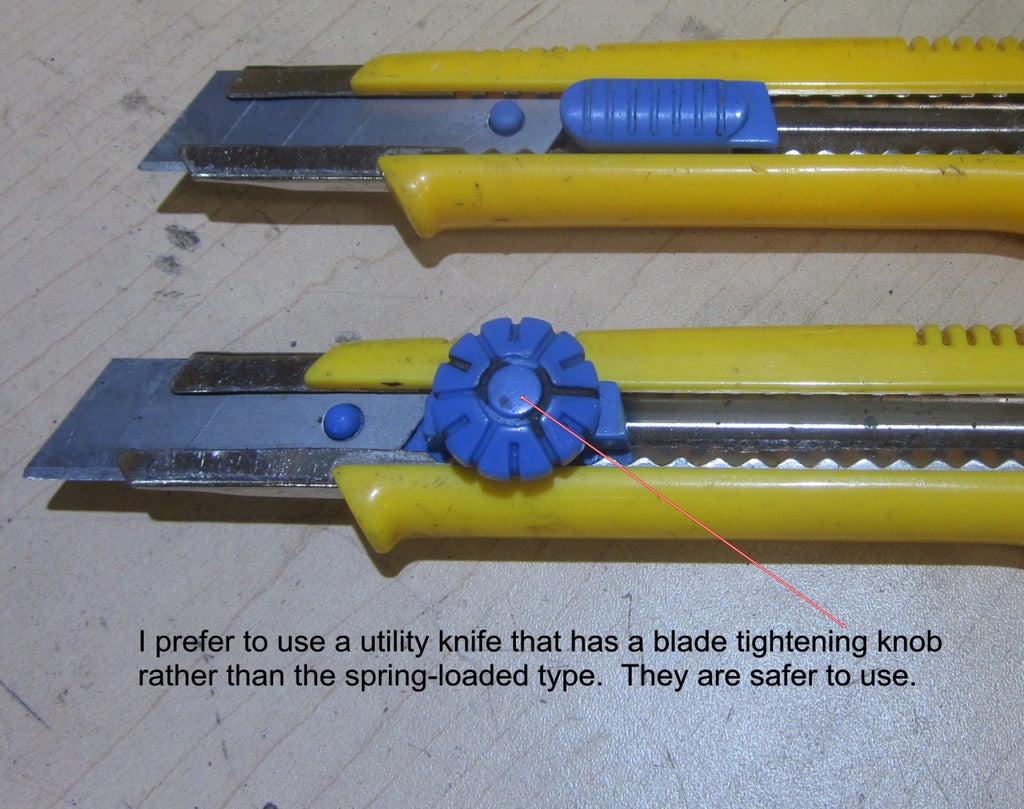

These photo steps show that it can be done using a utility knife. Also referred to as aviator snips these scissor like hand tools cut sheet metal materials up to 18 gauge in thickness accurately without leaving a ragged bent edge as the finished product. This eats away at the metal and leaves a very clean and smooth edge. They can be used in combination with handheld edge deburrers to produce very clean edges.

Open the scissors as wide as you can then fit the metal snugly between the blades. For thin sheets of metal you can use tin snips to cut through it. Start by taping both sides of the sheet metal directly over the line you want to cut and clamp the metal to a work station so it doesn t move. Water jets are surprisingly capable of cutting very thick sheet metal up to a few inches thick with very high accuracy.

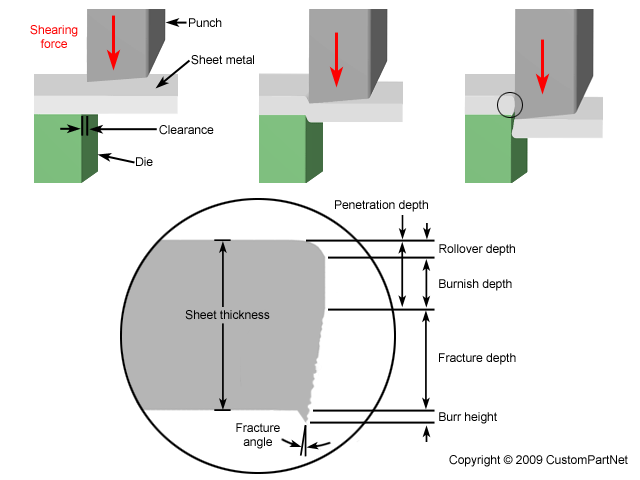

Secure the sheet metal to prevent slipping. Good old metal files are great for straightening cut lines in metal edges and for removing burrs and other imperfections. Think of cutting the metal as a school craft project only with bigger sharper materials. If you use metal shears to cut thin sheet metal such as duct metal it curls and can be difficult to flaten properly.

Run the point over the other sides to break those sharp edges. Then grip the saw with both hands and push the blade through the metal to cut it. As the groove in the point wears just move down the point to create a new groove and so on. If you have to cut a straight line clamp the sheet to a metal table with the edge to be cut just off the table.

To cut straight lines use an electric saw.