Ideal Roofing Screws

If you use a 2 500 rpm screw gun to drive fasteners into steel of this thickness then you will prematurely burn up the motor as well as the points of your screws he says.

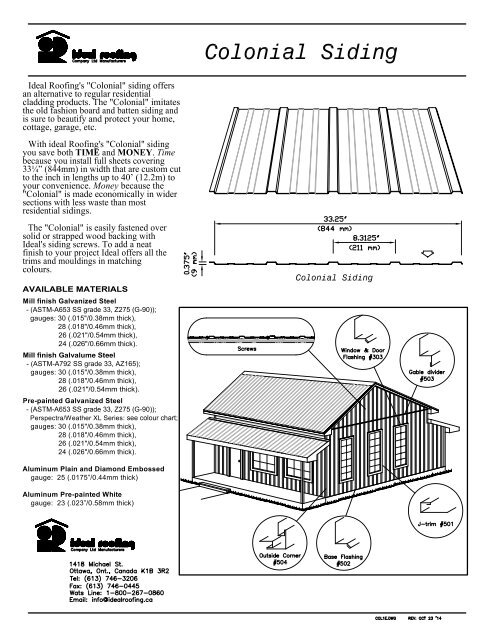

Ideal roofing screws. Install the roofing screws vertically along each rib in the panel. Webb says a 1 000 rpm high torque screw gun is ideal for fastening t5 self drilling screws into steel that is 1 4 inch thick or thicker. Thus ideal roofing offers a building envelope for virtually any kind of building either agricultural commercial industrial institutional or residential. 250 brown 12 x 1 1 2 hex regrip sheet metal roof screw.

Ideal roofing s ameri canapanel provides better protection against leakage with its built in anti syphon groove. Roofing screw best choice for fastening roofing sheets. This tight fitting overlap design allows for drainage through its anti syphon groove if water is forced inside as a result of capillary action. Find roofing screws at lowe s today.

Roofing screws are made of hardened carbon steel or stainless steel. The architecturally pleasing h f 16 h f 20 25 panel can be installed over a solid backing or over steel or wood purlins through oval slots with ideal roofing s specially designed fastening screws allowing for the contraction and expansion of the metal. Ideal roofing s home page. Roofing screws with drill points are used to fasten to metal structures.

Sharp point metal to wood siding screws. They can be used for metal plastic and fiberglass roofing applications. The washer under the screw head should seal to the surface of the panel without bulging or shifting. Ideal roofing is a leading manufacturer of metal roofing and siding steel building products steel decking steel roofing shingles steel roofing tiles roofing and siding trims and flashings.

Place the first screw about 7 inches from the bottom and each subsequent screw about 18 to 24 inches apart along the vertical run. Ideal roofing s home page.