How Tolder Copper Sheet With Silver Solder

This is not silver soldering.

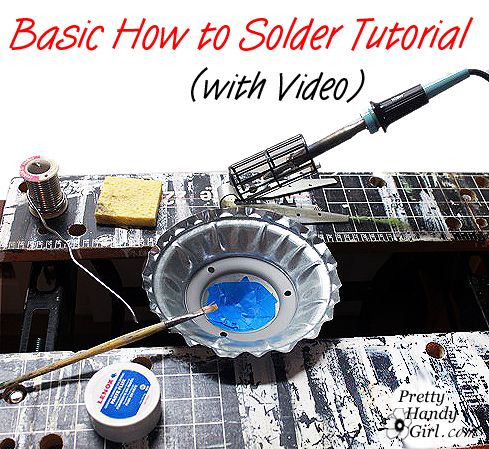

How tolder copper sheet with silver solder. As such the filler metals for soldering and brazing copper and copper alloy tube and fittings must have melting temperatures below this temperature. Make sure the area that is covered is roughly the same as the size of your silver sheet. Begin heating the assembled piece evenly to bring the solder to melting temperature. If your soldering is neat you will never see that silver line of solder.

If a silver bezel on a piece of copper bothers you then throw a nail or a piece of binding wire into a small cup of pickle. Apply flux to the outside of the tubing and the inside of the connector with the brush supplied with the flux. View the products. Rosin flux core lead free solder for.

The melting point of real silver solder is over 600 degrees c what you are using melts at 220 degrees c according to the card. Place your silver sheet to one side and apply a small amount of flux to the top side of your copper sheet. These are available with either 2 or 5 silver and are used primarily for joining copper to copper where if the metal is clean no flux need be used. Clean the inside of the copper fitting with.

Clean the outside end of the copper pipe with a piece of emery cloth until it is shiny bright. It s soft soldering with lead free solder. It will copperplate your bezel and also copperplate any offending solder. Clean and scuff the copper joint surfaces with plumber s brushes which have wire bristles.

The melting point of copper cu alloy uns c12200 is 1 981 f 1082 c. Silver solder can be used to join most common metals including mild steel stainless steel copper brass cast iron and dissimilar metals. For example for a. Brush generous amounts of flux onto the end of the copper pipe coating the entire circumference.

Once the flux is applied you can place the silver sheet on top of the copper sheet ensuring that the solder is face down on the copper sheet. Place the small bit of solder onto the flux painted side of the background piece and then place the foreground piece flux painted side down on top of the background piece. How to solder copper to copper hunker. They have silver with nickel alloy sides and a copper core.

How to solder copper with silver solder 1. Your copper pipe should be glowing red. The five flux cores allow fast soldering that uses less solder and transmits less heat to the joint.