How To Weld Stainless Steel Sheet Metal Without Warping

Welding heat sink applying a heat sink behind the weld or on the surrounding metal of a weld will help keep the the heat from spreading and allows you to weld without damaging the metal surrounding the weld as much.

How to weld stainless steel sheet metal without warping. The tig welding method is well suited to tack welding and wire brushed or ground before the final weld bead is laid on top. Another method used to join pieces of metal together is brazing. Intermittent rather than continuous welds help as does minimizing the amount of filler metal used. Correctly sizing a weld not only minimizes distortion but also saves weld metal and time.

An ounce of prevention the battle between hot cold. Weld heat input. By putting the metal between a dolly and a swinging hammer you are slowly stretching the metal out by striking on it each time think of kneading pizza dough. This relaxes the metal and flattens the weld which in the end allows you to control the warpage in the panel.

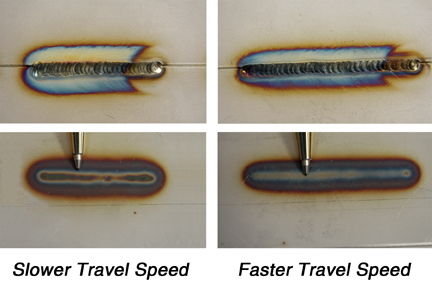

Though weld shrinkage cannot be prevented it can be controlled by following these steps. The heat input welding speed should be kept within the parameters for the electrode type and size. Welding distortion is the result of the action of internal stresses which are produced while welding. Welding distortion or deformation or warping of weldments during welding is a natural outcome of intrinsic non uniform heating and cooling of the joint.

There are many materials that can be used to make the filler metal. Learn why mig pulsed mig tig and pulsed tig are the ideal choices when welding sheet metal. This is very important to keep the shape of the panel you re welding. The bigger the weld the greater the shrinkage.

The warping of metal during the welding process is due to the high levels of heat involved. Use anti warping devices and techniques. Brazing is a similar method to soldering and welding and requires the metal to be melted so they can be joined. Use intermittent welds instead of continuous welds where possible to minimize the amount of weld metal.

Design and welding should be addressed to minimize this sort of warping. Minimize the amount of heat put into the weld. Here s a list of tips that help reduce warpage in sheet metal fabricaitons. Even seasoned pros who perhaps haven t had a serious issue with a warped piece of sheet metal in a long time can gain new insight from some of these tips.

In this technique a filler metal is melted and flowed into the joint where the connection needs to be made.