How To Tig Weld Galvanized Sheet Metal

It depends on what you are welding and how critical the application.

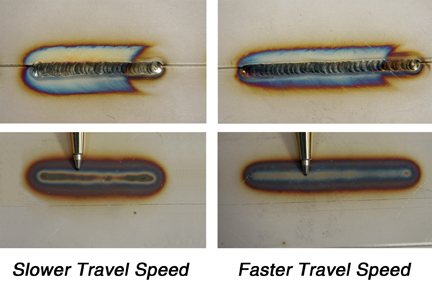

How to tig weld galvanized sheet metal. Good ventilation is required. Welding galvanized metal is dangerous because zinc oxide is released into the air as the metal melts. You are right about removing galvanized coatings sort of. When welding the steel that is galvanized the welder has to be set a bit hotter than normal and make sure to give a wiggling movement between the workpieces that are galvanized in order to ensure a good weld pool at the beginning.

Using this process enables more than effective work on thin materials as it provides high precision and high quality work. How to weld galvanized steel. Below are a few recommendations on how to weld on galvanized steel. Galvanized steel welds similar to uncoated carbon steel when properly prepped.

If you can work outside when using an arc welder. Ditch a 1 8 inch tungsten electrode for something much smaller like 1 16 inch tungsten. Use an arc welder to weld galvanized steel. This is a big claim and these filler metals certainly have some merit but there are other practical ways to successfully weld galvanized steel.

Tig welding for sheet metal. Welding tips and tricks answer. How to weld auto body sheet metal with a tig welder the best two electrodes for welding auto body sheet metal is either ceriated tungsten or thoriated tungsten. They were made from galvanized sheet metal and we didnt clean crap.

Welding of the galvanized steel is done similar to the welding of bare metal with a difference of low vaporization temperature in the metals with zinc coating. For example i worked for a while welding big tables that held furniture stripper chemicals. Have you ever welded something so thin and worn out that all you do is blow holes in it. We just welded em.

A standard arc welder is undoubtedly the best way to weld galvanized steel. If you attempt to weld galvanized steel without removing the galvanizing from the weld area the weld puddle will pop blow out and create a health hazard to the welder and any individuals in the immediate area. Manufacturers of filler metal have come up with special wires that promise to eliminate porosity. Forget the larger 1 8 inch tungsten electrode and use a smaller one.

I use an acetylene torch to burn off galvanized prior to welding and utilize a. Don t attempt to weld thin materials like sheet metal with flux cored wires which put more heat into the base metal. Arc welding is a versatile method that uses alternating currents to create a high heat arc that melts your flux. Tig welding sheet metal.

Did you want to learn how to work around that and deliver a solid re. If the galvanized is not burned off prior to welding then a poor weld will be the result.