How To Shape Purlin For Corrugated Roof

Snap a chalk line horizontally across the roof two feet down from the top.

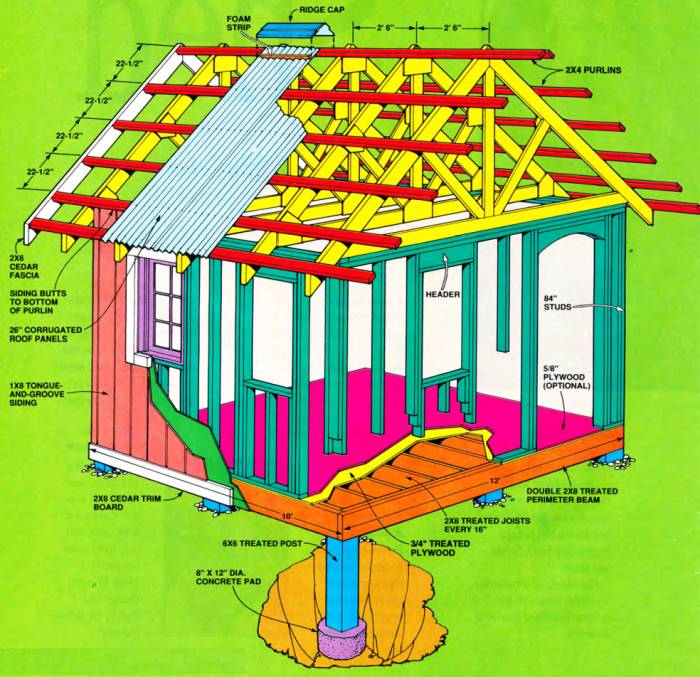

How to shape purlin for corrugated roof. Setting corrugated metal roof purlin spacing in a proper distance is an important part of the entire process. Adjust door construction to desired size. The purpose of the purlins is to provide a solid foundation for the metal roofing panels and trim to be screwed to. Apply front and back panels similarly to side walls.

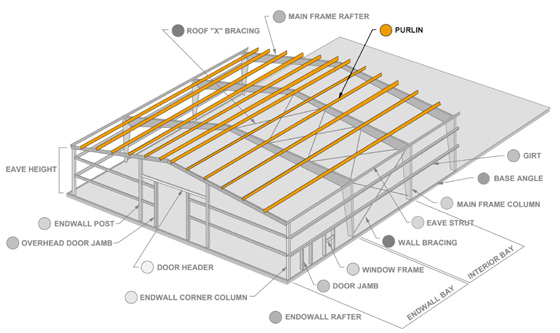

Meanwhile there are two kinds of purlin span for metal roof based on the shapes which are the c purlins and z purlins. Proper spacing will offer attachment security that resulted in optimal stability. Purlin spacing should suit the end laps required for the size of sheet to be used. Overlap roof panels one corrugation away from prevailing wind and nail to rafters starting from one end.

Insert two equally spaced nails into the rafter. Roof decking is often also used as a diaphragm to transfer wind or seismic loads to the lateral bracing system below. The overlaps ends and sides depends upon the sloop of the roof see below. Install vent as close to roof peak as possible.

The decking is sized to resist the bending caused by these loads. The rafters are generally spaced every 16 inches on center. Lay the first purlin at the ridge of the roof down to the chalk line beginning at either corner. Corrugations should run in a straight line between the highest and lowest points and at a right angle to the purlins the intermediate supports.

Corrugated metal deck and siding is used for roofs and walls respectively to span between purlins for roof loads or between girts for wind loads. However if your metal roof has another supporting method the exact spacing is not. Purlins are non pressure treated 1 x 4 x 12 lumber that is installed on to the roof in a specific layout pattern and screw pattern. Fasten the purlin with 16d common nails into each vertical rafter.

Corrugated sheet roofing material is widely available and easy to use.

.jpg)