How To Secure Sheet Metal For Ducting

Some manufacturers recommend against using sheet metal screws to secure dryer duct sections because the screws collect lint.

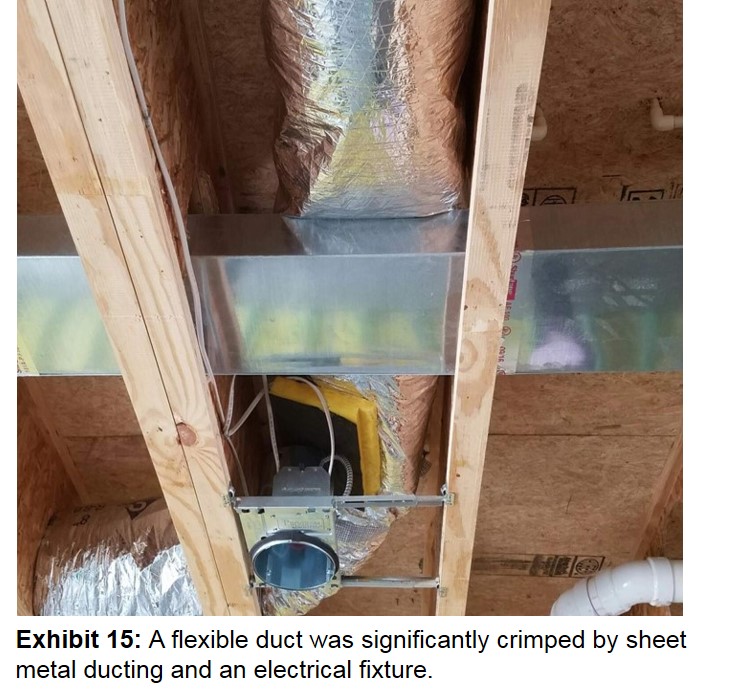

How to secure sheet metal for ducting. Sheet metal ducts must have insulation covering them. Turn the screw at high speed on the end of a drill and bit while pushing it firmly against the. Ryan shanahan i ve been told to avoid using metal screws with flex duct because the flex can tear easily once you create a hole. Press a continuous strip of foil tape to all longitudinal seams along straight runs of duct.

The three screws will prevent the two ducts from moving and separating at the new seam. Welding can be dirty and time consuming. Adhesives for example have been known to fail especially when heat or vibration are present. Step 4 use screws and foil tape to hold the fiber board duct pieces together.

Insert 1 2 inch self tapping sheet metal screws through metal ducts where the ends come together. Thin sheet metal is a popular choice for use in packaging because it is lightweight and takes up less space. You can even use three sheet metal screws behind the first rib or two of the duct as long as you use mastic under the duct at the sheet metal connection. If necessary switch the wires to reduce the blower to its lowest speed.

And sheet metal screws or loose. However finding a suitable fastening approach has not been easy. Also if you have ever tried reaching into a dryer exhaust duct to clean it by hand and had your arm ripped open by the sms screw you may have another objection. Insert two additional screws along the seam with equal spacing between the three screws.

Add support straps or nylon ties to support the duct. Check the speed of the blower motor on the furnace.