How To Press Form A Hole Collar In Sheet Metal

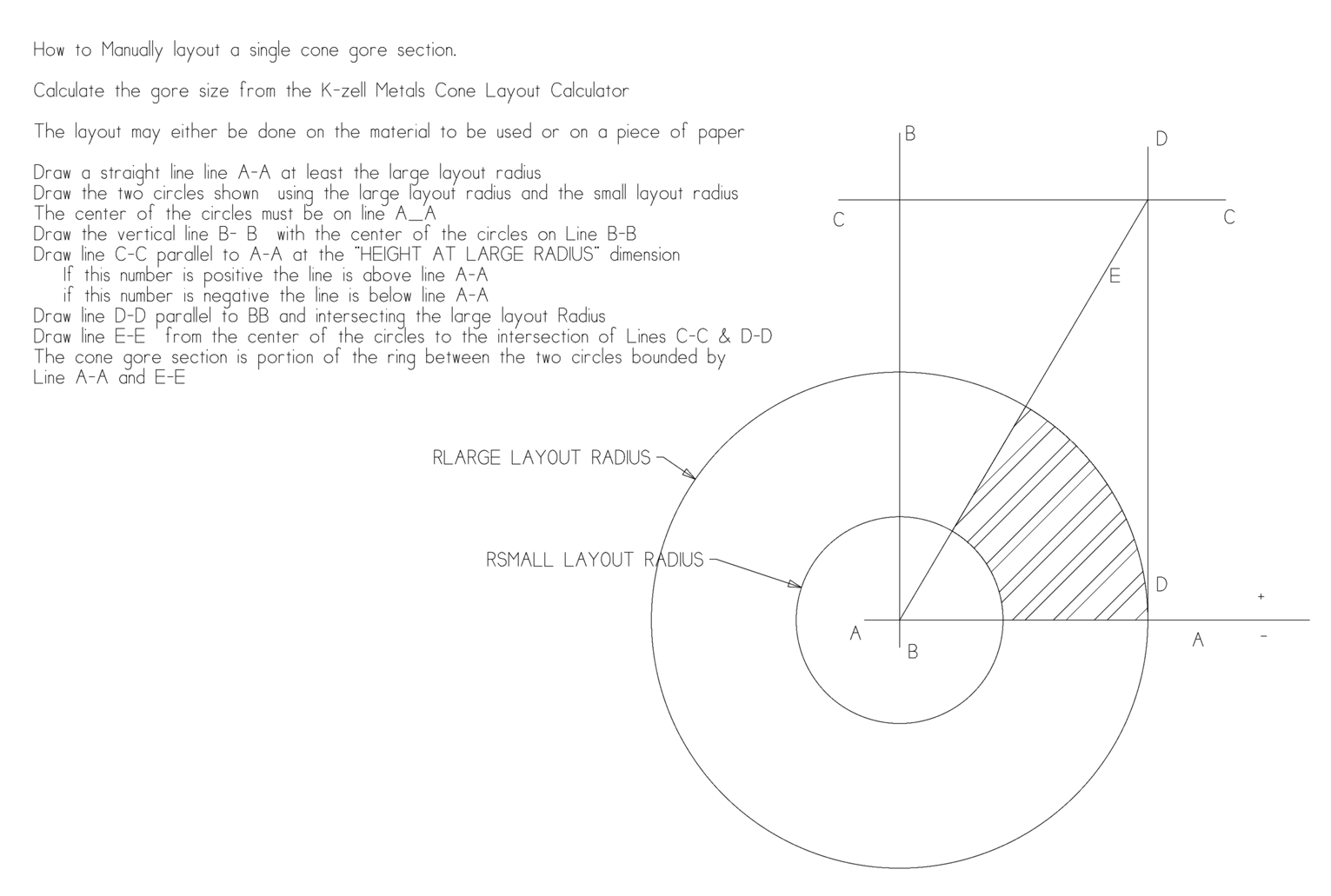

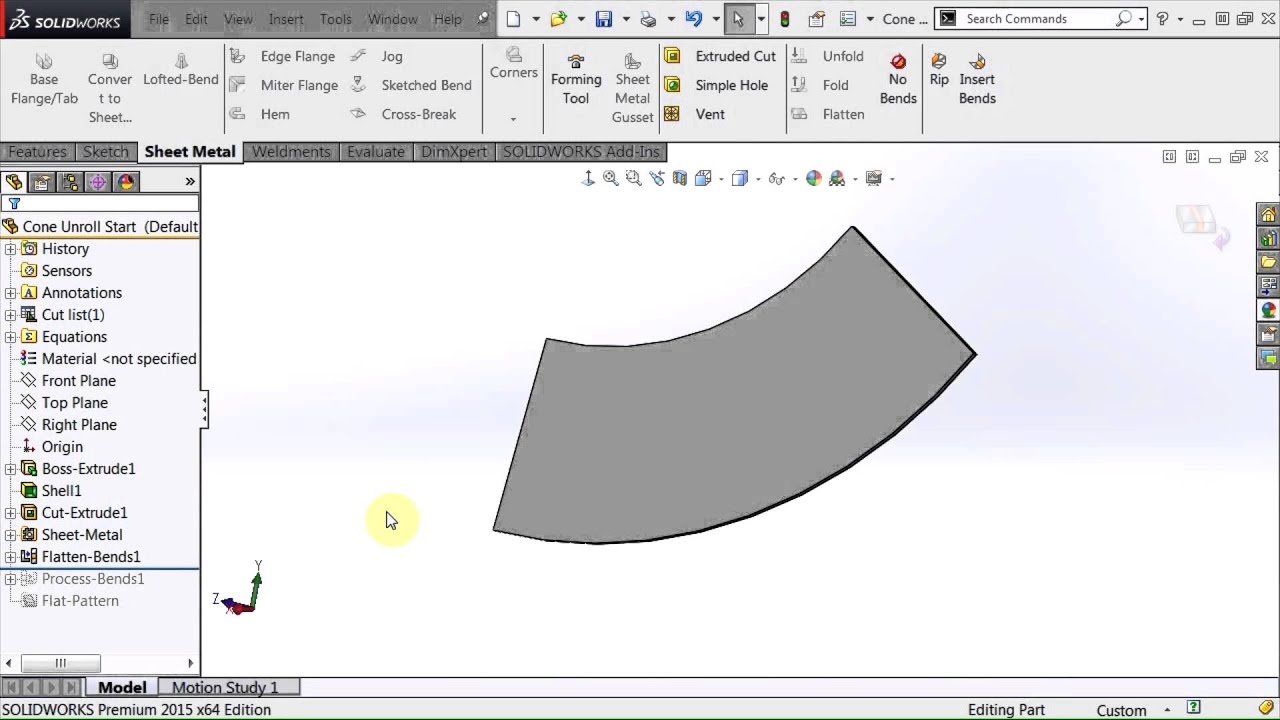

View the cone instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections.

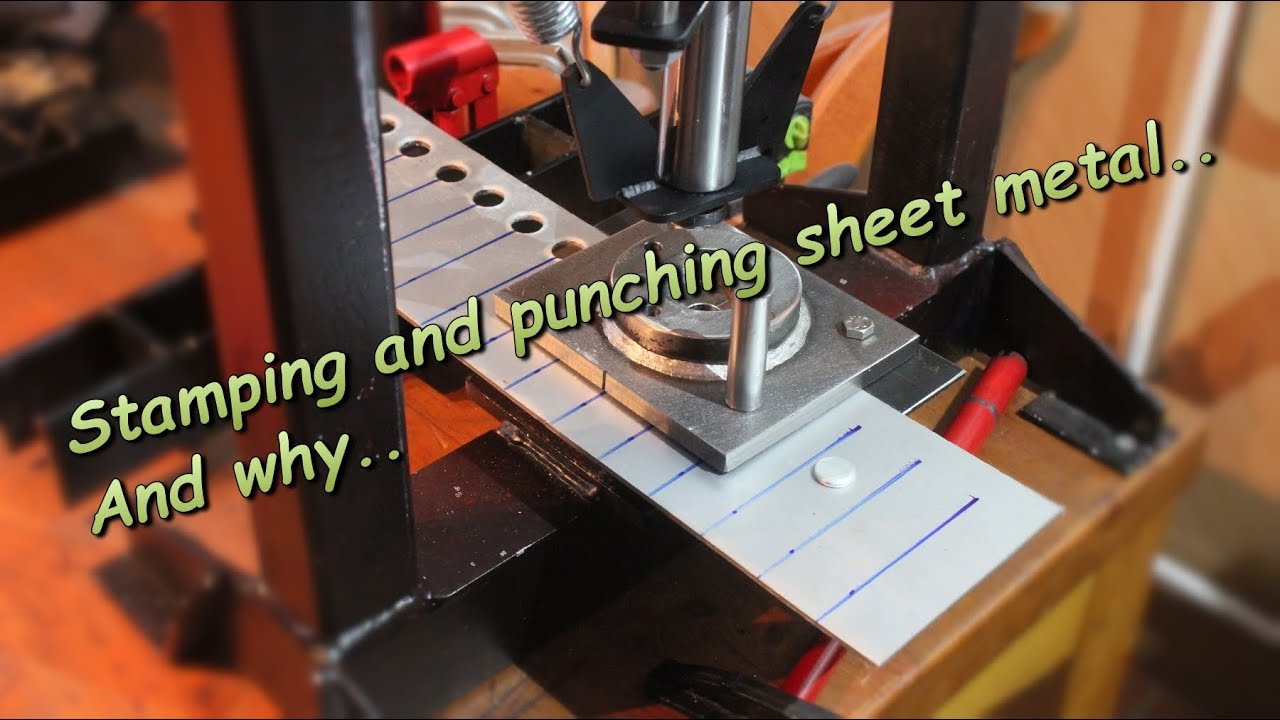

How to press form a hole collar in sheet metal. With one easy step you can flare an existing hole in sheet metal panels for improved strength and appearance. Place your sheet metal on your steel block and position your centre punch at a central point in your cut out design. Https amzn to 2kstzae sheet metal hammer. This is especially relevant for press fit assembly a process whereby one part is inserted tightly into a hole in another part with a single quick stroke 1 to 2 seconds.

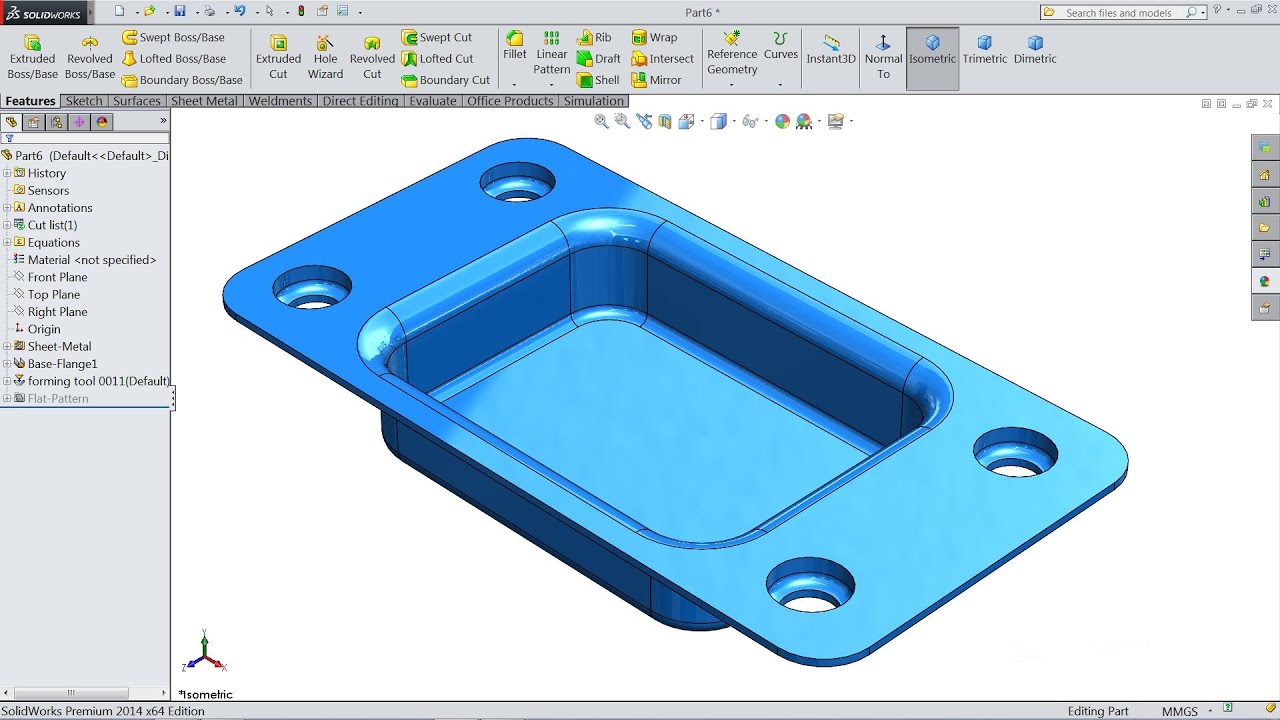

Extruded holes are formed up or down to create a formed collar on one side of the material figure 9 commonly tapped as well also on the punch press extruded holes are used with thread cutting screws or other fasteners or they are used as locators for other press fit applications. Design engineers use many formulas to estimate the required force and related pressures and stresses for each press fit application. Place the sheet metal in the correct position on the positive die and slide the negative on top. It s like a little metal sandwich.

Https amzn to 2ndf97w the best tin aviation snips. Lance and form assemblies can be any size and shape and forming them generally requires less press power than punching a hole of the same size. Tap your hammer to leave an indentation on the sheet metal. In manufacturing ironclad formulas for success are hard to come by.

Https amzn to 2mkd0sj large screw driver. Dear you all today i would like to introduce how to make sheet metal pressing tool. Using these tools the punch press lances cuts the material and creates a form. Depending on the tools you have you ll now need to punch or drill a hole where the indentation has been made to produce an accurate hole in your sheet metal.

Bench pressor by simply placing the two halves of the die on either side of the properly sized hole drawing the tool together with a standard wrench. 16 gauge steel is the maximum thickness. Pump arm of hydraulic jack to advance lower platen which rests on the head screw of the jack to press the die and metal padded with flexane against upper platen as far as it will advance. It allows you to determine either the size of raw material needed or the number of gore sections to fit on your available material.

They work great in our mittler bros. This action will force the flexane a rubber or urethane compound to push the sheet metal into the die. Sheet metal cone calculator.