How To Press A Hole Collar In Sheet Metal

3 dovetail duct start collar.

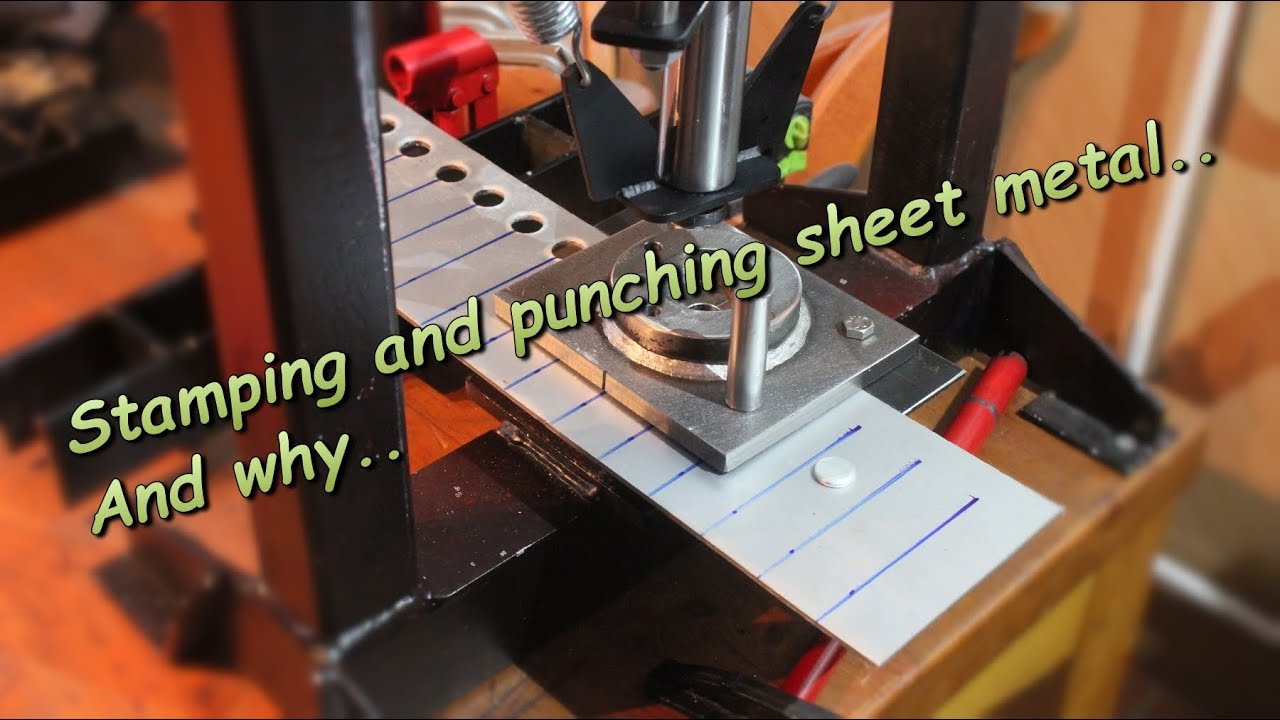

How to press a hole collar in sheet metal. Design engineers use many formulas to estimate the required force and related pressures and stresses for each press fit application. Tap your hammer to leave an indentation on the sheet metal. Coining one of the three types of bending for sheet metal where the punch penetrates into the sheet metal under high tonnage forming a consistent bend. View the cone instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections.

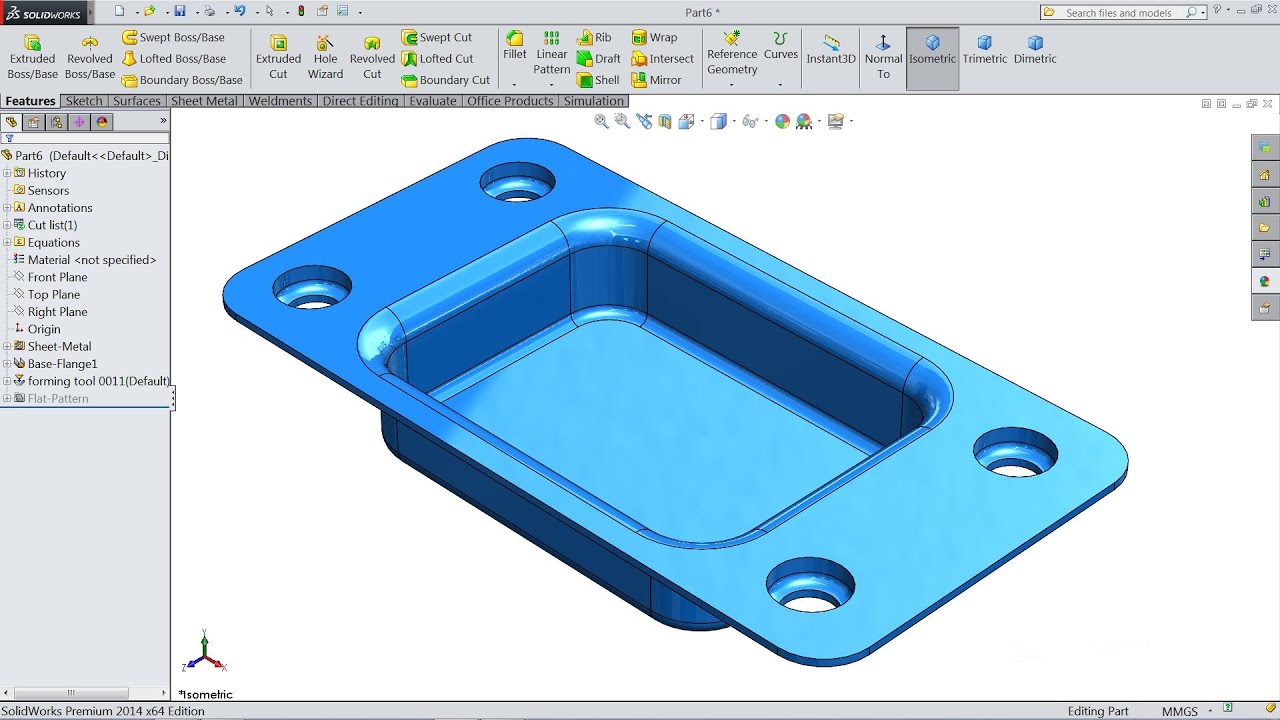

Press brake and slip roll. Sheet metal flaring tools. Start collars are cosidered best practice and most economical way for starting a new duct run from your supply air or return plenum. I think the way to get from here to there is to model the part without using sheet metal tools the sample.

Bench pressor by simply placing the two halves of the die on either side of the properly sized hole drawing the tool together with a standard wrench. Question asked by misty ratzlaff on feb 12 2008. It allows you to determine either the size of raw material needed or the number of gore sections to fit on your available material. Box bending the process of bending a 4 sided sheet metal box.

They are manufactured from the highest quality galvanized sheet metal and to our exacting standards. 16 gauge steel is the maximum thickness. They work great in our mittler bros. Paul ricalde 2 162 951 views.

This is especially relevant for press fit assembly a process whereby one part is inserted tightly into a hole in another part with a single quick stroke 1 to 2 seconds. With one easy step you can flare an existing hole in sheet metal panels for improved strength and appearance. Cut round hole with harbor freight sheet metal sheer duration. How to install a start collar the duct shop duration.

To a disk but not both in the same part. Depending on the tools you have you ll now need to punch or drill a hole where the indentation has been made to produce an accurate hole in your sheet metal. Sheet metal cone calculator. What i did was extrude a disk cut a hole add a curved flange to the id of the washer add a cut to create a gap.

But the truth is numerous factors including chamfers at the edges collars near hole and spaces between drilled holes matter in the sheet metal world.