How To Nail Down Tin Roof

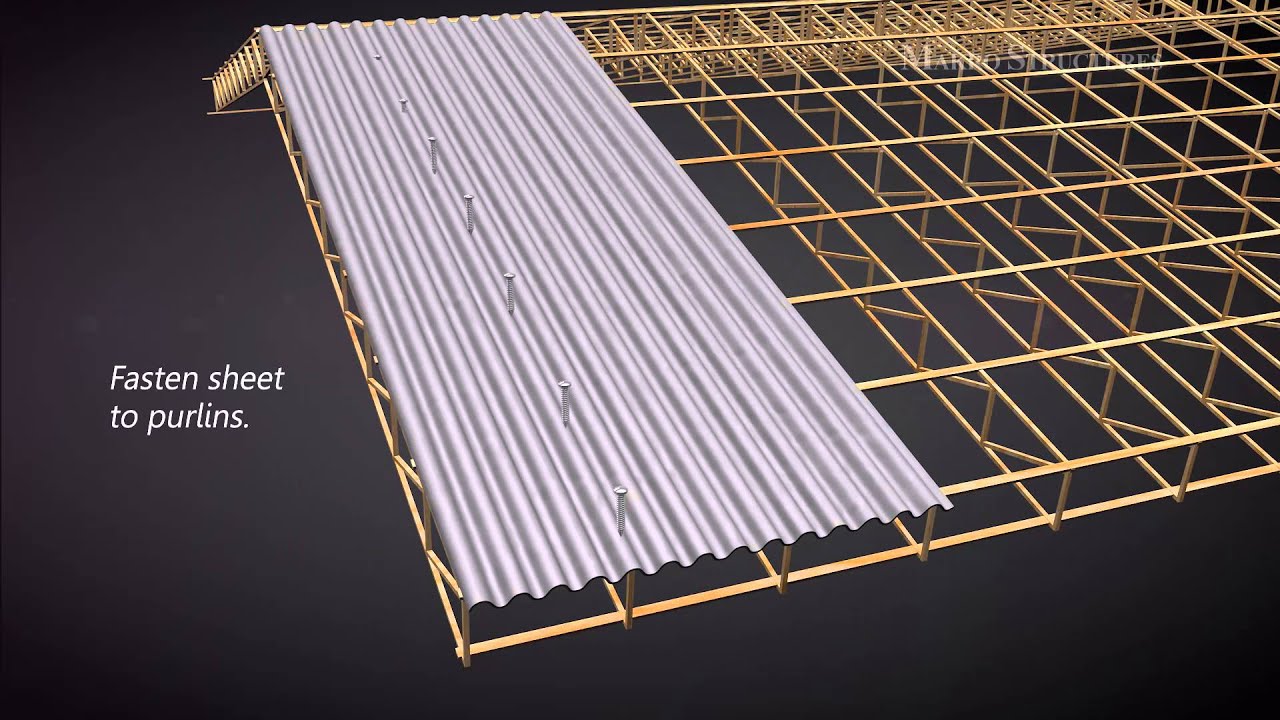

Pre drill the holes and use 10 by 2 in 25 4 by 5 1 cm screws with polycarbonate washers.

How to nail down tin roof. Step 3 buy the materials. Continue across the roof until it is completely covered lapping over the previous panel by at least 2 5 inches 6 4 cm minimum. If you come across any large nails that are sticking out either remove them and put them in your debris container or. Lay the starter row of metal shingles at the drip edge and affix to the roof with metal roofing nails.

Screw down the panels. Most metal shingles will be attached to the roof using metal shingle. Most box stores sell corrugated that is about 32 ga. You might need to cut and secure an extra segment to fill the end of the row.

Decide what type of tin roof you want by selecting either an r panel or v crimp style. Insert two long nails into the wood stripping at each rafter point marked in chalk. The lower edge should be approximately two inches from the roof edge. Step 1 select a tin roof type.

Start at the highest point and the furthest point from the trash container and take off all the old shingles flashing. Drive a pair of 8d nails through the wood. Adjust the lap so that the last panel completes the coverage without making a cut lengthwise. How to install a tin roof.

We do recommend it however. Step 5 install slat. Step 4 remove the current roof and line it. Purlins are non pressure treated 1 x 4 x 12 lumber that is installed on to the roof in a specific layout pattern and screw pattern.

Use the lower edge of the roof as a guide and install nailers end to end across the roof with the lower edge two inches from the edge of the roof. Work up from the initial row starting at the lower corner in a diagonal pattern staggering the shingles to prevent gaps. The purpose of the purlins is to provide a solid foundation for the metal roofing panels and trim to be screwed to. Step 2 take measurements.

Do all roofing projects require purlins. For an r panel style. Corrugated metal or thicker. Nailing tin roof dumb question the best way is driving screws with rubber washers on the ridges if you use 24 ga.