How To Mark Curves In Sheet Metal Joints

I have bent 3mm sheet up to 300mm wide like this.

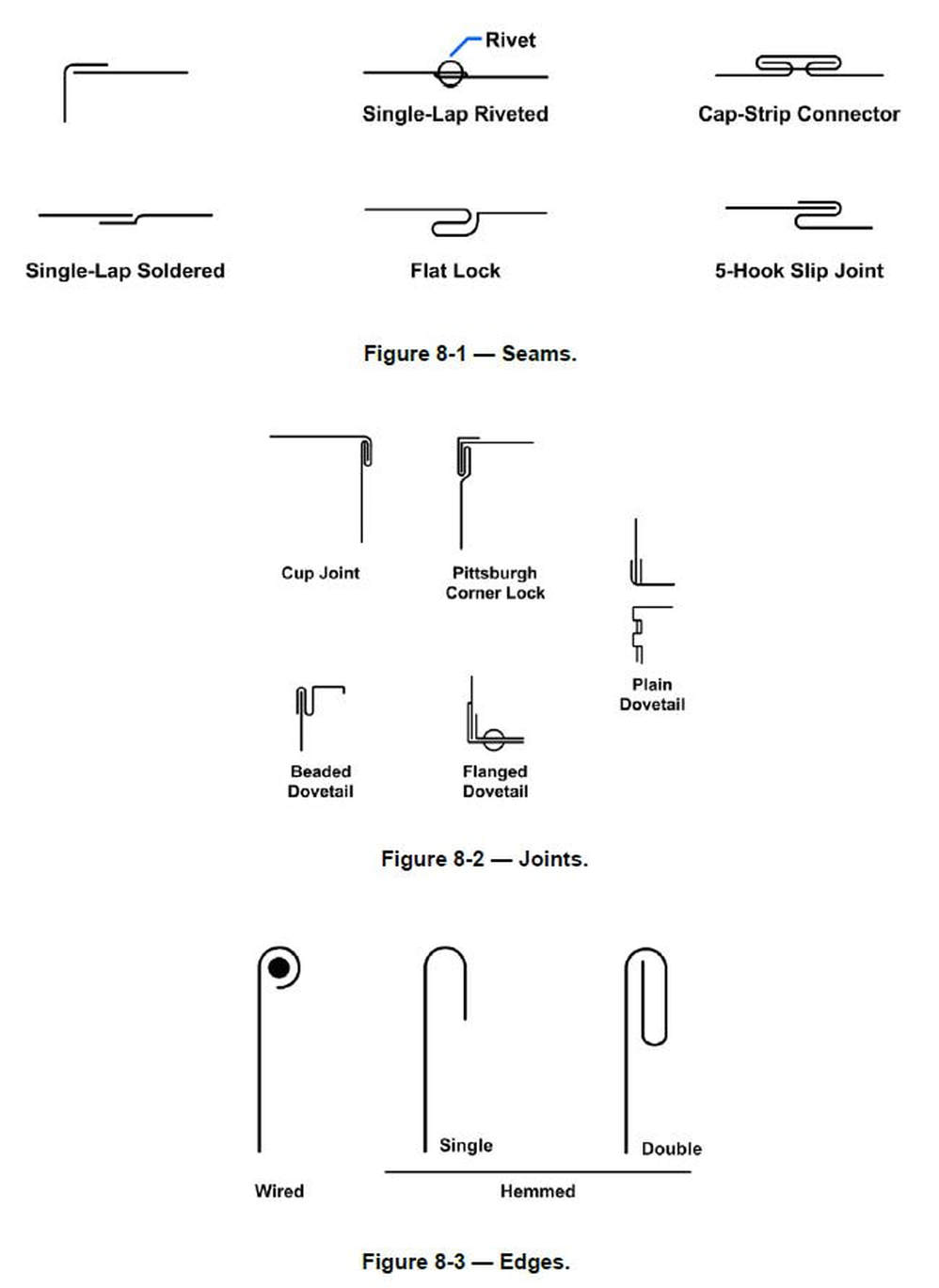

How to mark curves in sheet metal joints. It consists of two folded edges that are locked together with a hand groover fig. The main purpose is to use the spot welding process to reserve a row of solder joints on the two sheet metal. A lap joint is the simplest way to join sheet metal. Make sure the first bend mark lines up exactly with the curve in the form so that the bending will begin in the right spot.

Artist kevin caron shows how to create a curve he can cut out on an aluminum metal sheet for the public sculpture he s working on. To make the joint simply overlap the parts by at least 1 4 or as specified by project instructions. Sheet metal clinching joint creates a button type positive connection between two or three layers of sheet metal. Clamp the box section on top of the shims feed the metal through and pull up then feed the metal through a few mm at a time gentle tweaks using the long side when you reach the middle turn it round and repeat.

Clinching joint is a type of permanent sheet metal joining operation that involves joining sheet metal parts using cold forming operation. Note watch out for overbending the workpiece. Establish a vertical line on your work area at 90 degrees. Hi all i m trying to create a tank with corrugated sheets i can make the corrugated sheet but i can t bend it.

It is used to join different material and sheet thickness parts. Here is an example photo and autodesk fusion360 header nav label product name. 2 57 is one of the most widely used methods for joining light and medium gauge sheet metal. For 3mm i use a big piece of angle iron.

When making a grooved seam on a cylinder you fit the piece over a stake and lock it with the hand groover fig. Then drill rivet holes through both pieces. Using protective gloves hold the free end of the metal sheet with one hand and with the other hand use a mallet or hammer to begin bending the sheet down and around the curved radius of the wood form. Directly melt the local sheet metal material at the welding head to complete the sheet metal connection.

And pop rivets provide a quick effective means of fastening a lap joint as shown right. Use this intersection as the center point and draw a circle to represent the larger cement pipe s outer edge with a diameter of 23 25. In the above content we introduced various joining methods of sheet metal.