How To Make A Sheet Metal Duct Takeoff

Step 10 bend the metal at 90 degrees.

How to make a sheet metal duct takeoff. Open the clamp mechanism of your sheet metal break and insert the end of the metal with the lock form. In fact sheet metal use in hvac is greater than all other materials combined. 4001 mark iv parkway fort worth tx 76106 phone. They are manufactured from the highest quality galvanized sheet metal and to our exacting standards.

This provides a transition from duct board plenums internally lined plenums or insulated register boxes. The sheet metal shop is a long ways off. Assemble the metal ducting like a zipper when assembling pipe start at one end and work the seam together like a zipper. Use your leg a workbench or the ground to support the back side of the pipe.

The steel and aluminum used for ductwork is a high achiever in the 21st century move toward sustainable buildings because of the high recycling rates and cleanliness. Round takeoffs range from those using scrap sheet metal pipe with tabs cut on one end to those using a traditional tap in side collar or sheet metal elbow. Cut a length of duct equal to l plus 2 inches using tin snips. You can t get tees at the local home center.

Called sheet metal workers. Push the metal through until the 1 4 inch marks are lined up with the clamp edge and clamp the edge down on the metal. It fits a variety of duct board thicknesses for convenience. Arrange the offset in the same orientation as the installed duct and mark the offset side which is the one closest to the obstacle.

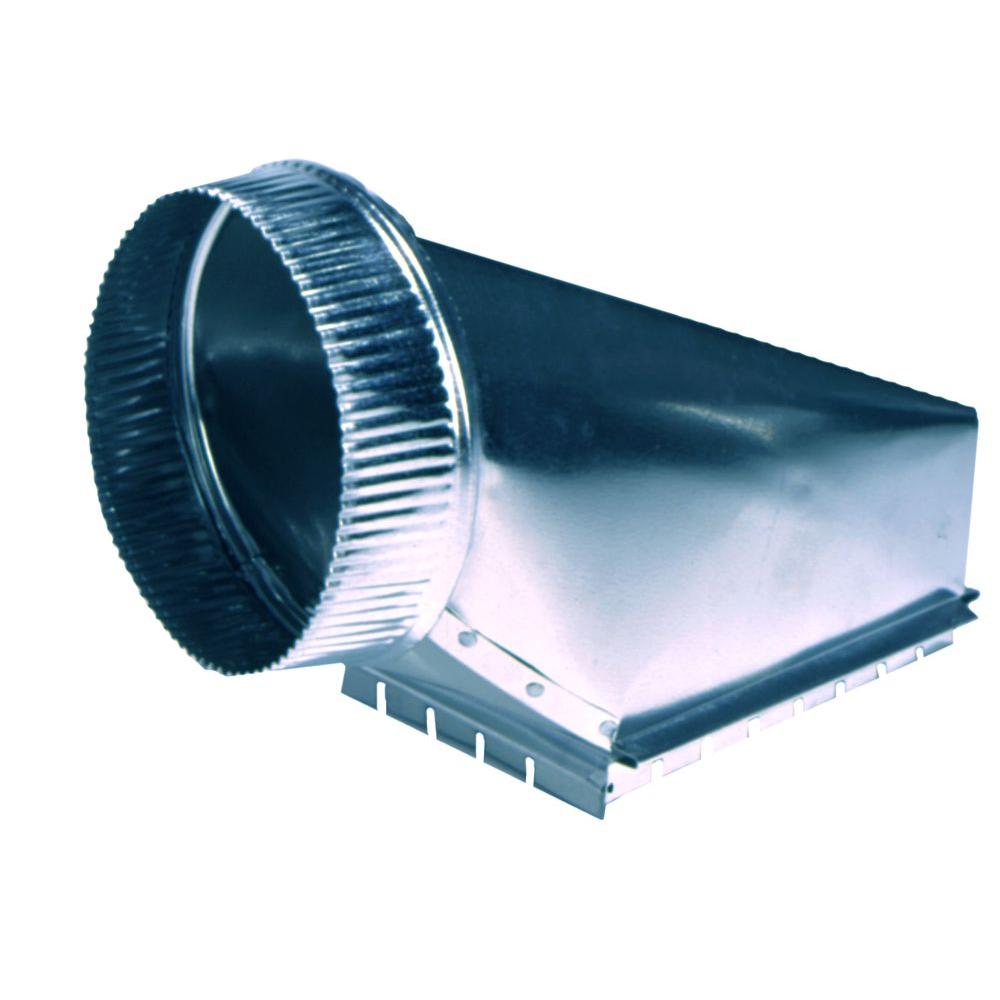

You need the extra length to create a 1 inch flange on either end for connecting the duct. Use one hand to keep the two edges close and the other to apply downward pressure. The one thing they all have in common is the opening mounted to the duct is also the same size as the branch duct it feeds. The master flow 4 in.

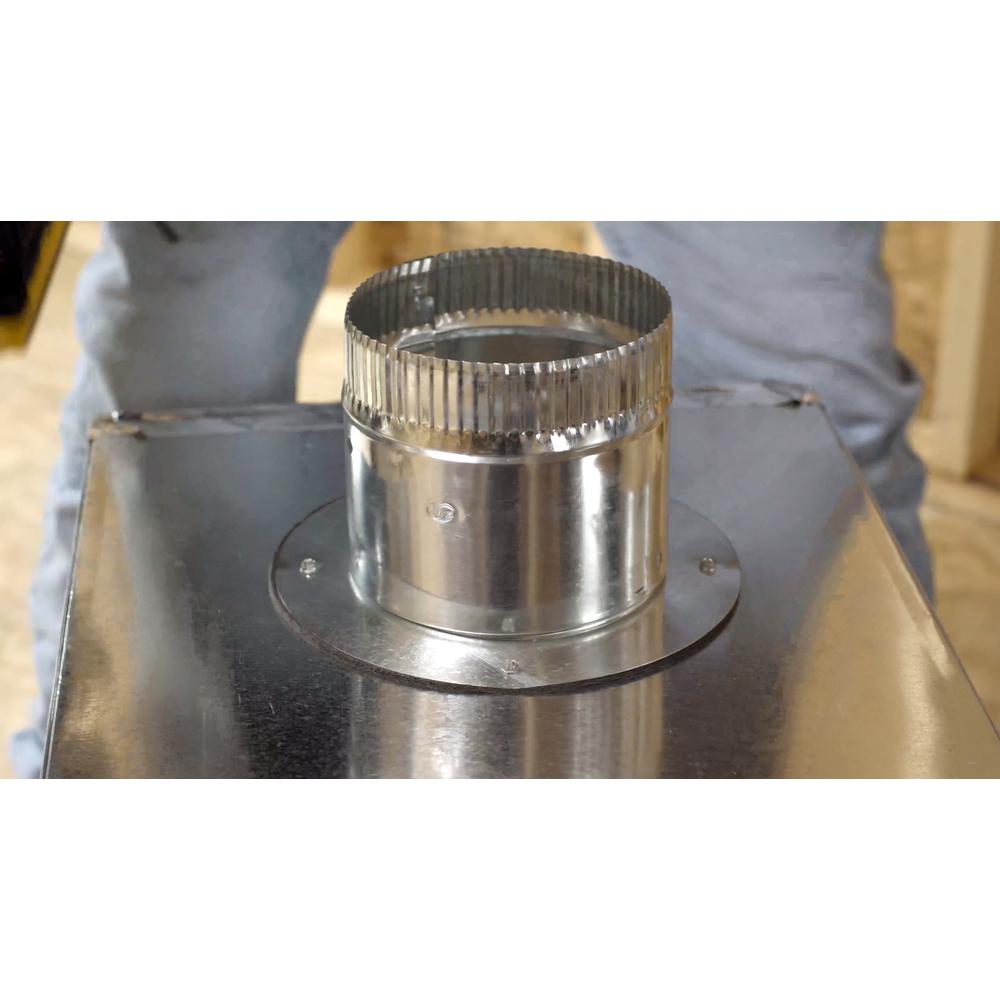

Start collars are cosidered best practice and most economical way for starting a new duct run from your supply air or return plenum.