How To Make A Sheet Metal Box With Curved Edges

This will create a lip.

How to make a sheet metal box with curved edges. You ll be bending over the edges of these flaps to make smooth edges for the top of the box. It is easier to cut off a 4 x 12 strip if you have a 12 x 12 sheet first then cut two 3 1 2 pieces from that strip. Repeat steps 1 5 for the opposite side of your box. You can create the perfect uniform radius with these bevel heads.

Lower the clamping bar handle down to clamp your metal into place. Minimise the gap setting to the least value allowed. We start the box by making its sides. Insert the first edge into a bending brake.

Step 2 is to tack weld the cornerfill into place. Use your bending leaf handles to slowly fold your sides and tabs to 90 degrees. Step 3 weld all seams. What you can t do is unfold it.

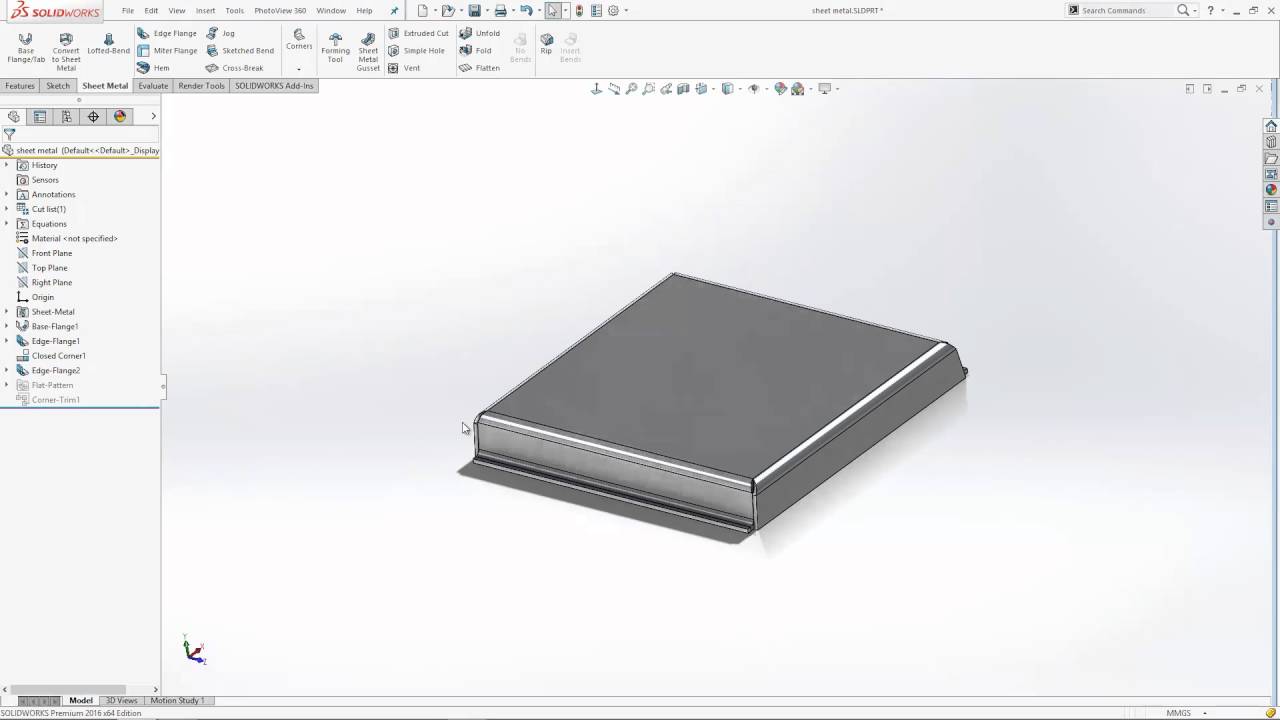

Once all of the squares are cut out you ll be left with the four flaps. It s suppressed in the flat pattern. Model a baseflange with the radius down to the bare minimum. This is how easy it is to make a rounded edge on metal.

Bend the edge 90. So mark out two 4 x 3 1 2 sections of sheet metal and cut it in the metal shear. Return your bending leaf to neutral position and lift up your teeth to remove your bent metal. Rounding metal with the bevel heads from beveltools ensure a smooth and consistent rounded edge on sheet plate pipe and hole.

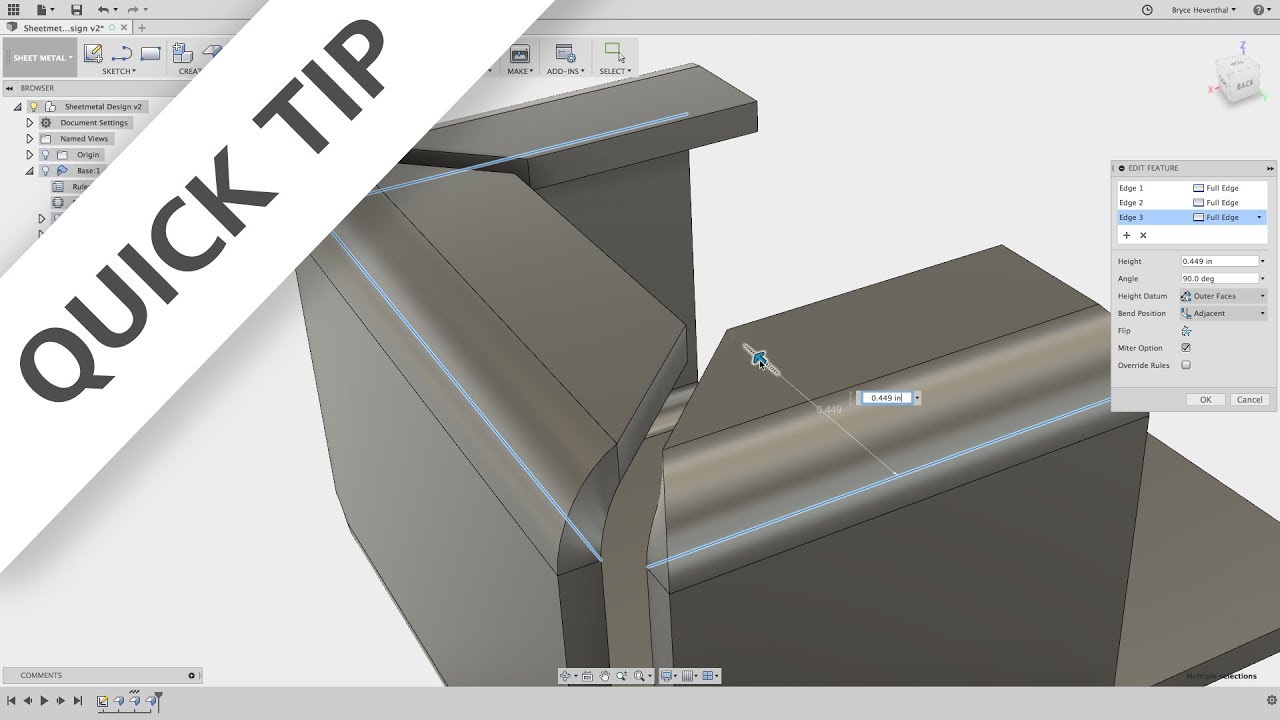

Create the rest of the bends with the mitre flange command. Make sure that it is lined up with the line you measured earlier. Now if you make the box by creating an extruded rectangle add fillets to all of the edges and corners and then shell the thing outward you can make that into a sheetmetal and add louvers and ports and stuff like that. Step 1 is to design the corners like shown in above image.