How To Figure Valley Tapered Panels For Standing Seam Roofing

Corrugated metal is 36 inches wide.

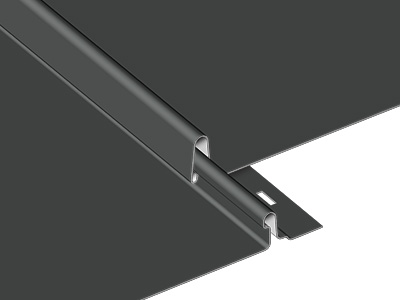

How to figure valley tapered panels for standing seam roofing. Standing seam roofing is among the most weather resistant and durable roofing options. Before installing the panels place a bead of sealant tape along the eave flashing and on top of the valley cleat. Divide the length of your roof by the width of the metal. Roll forming and installing a tapered roof can be a complex and demanding type of job.

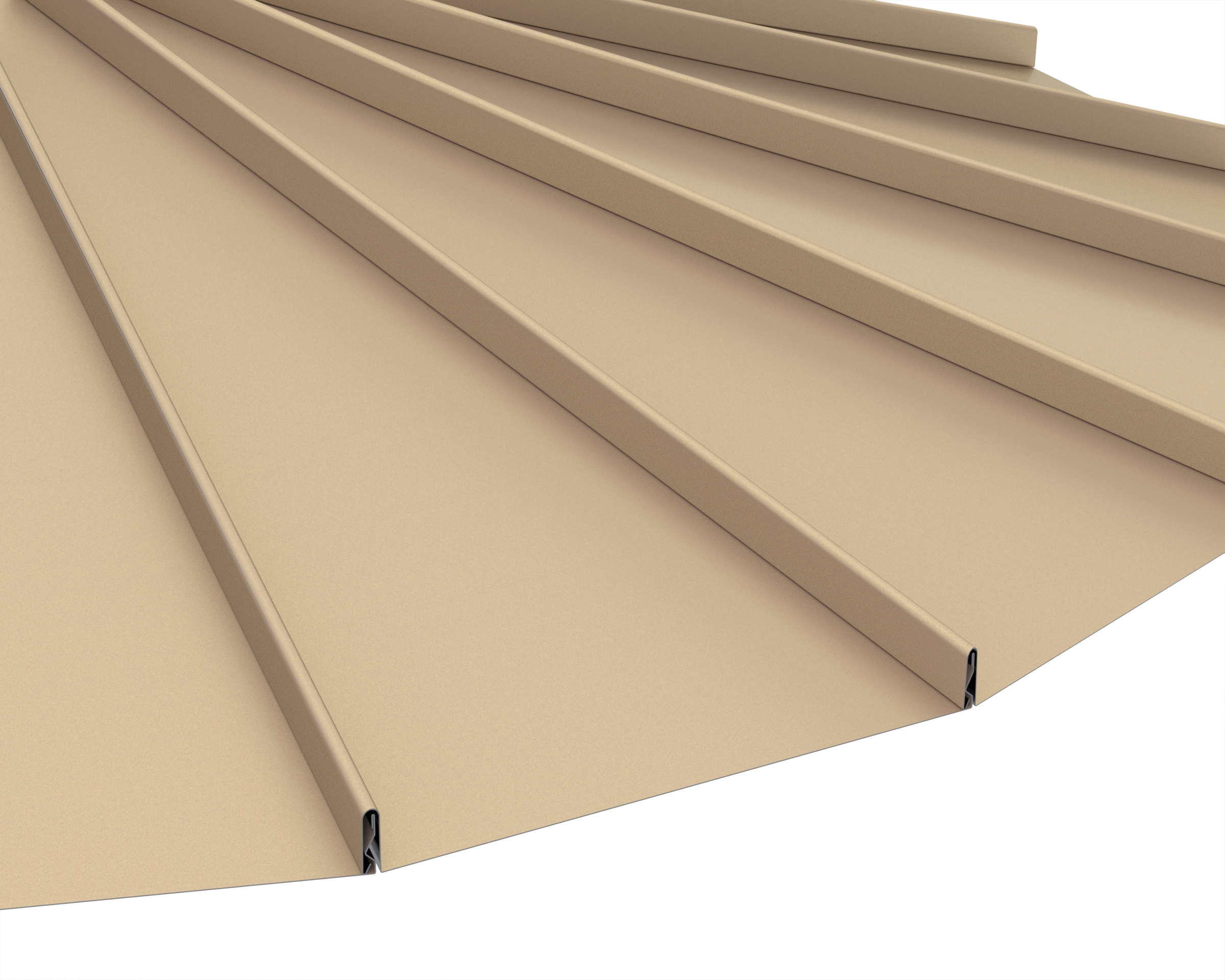

Because of the nature of the design there are usually more cuts and bends involved in making the panels. It also requires a certain degree of expertise to make the panels on site. Cut the climate guard panel at the appropriate angle and length to allow for a 1 inch hem at both the eave and valley cleat. For example standing seam metal roofing is 24 inches wide.

Going around and around with america s favorite roofer. Fasten with screws spaced 12 inches apart. This is the number of metal panels needed for one side of the roof. This instructional guide is based on fabral s nailing strip standing seam system with 1 ribs.

In our example we will use 24 inch standing seam roofing so we will divide 360 inches by 24 which equals 15. Now you can start cutting and hemming panels for the valley. Placing the first tapered standing seam panel. It takes more skill and experience to cut panels for a tapered roof than to run panels for a standard standing seam roof but the result can be more visually appealing and more profitable.

It takes more skill and experience to cut panels for a tapered roof than to run panels for a standard standing seam roof but.