How To Cut Beveled Plug Door In Sheet Of Plywood

Grasp the pencil between your thumb and finger.

How to cut beveled plug door in sheet of plywood. By our experience using a proper blade with a masking tape provides perfect results. Hold the door on each side with the handle facing forward. Refer to figure 6. Next lift the rear of the saw but keep its front edge pressed firmly down on the sheet.

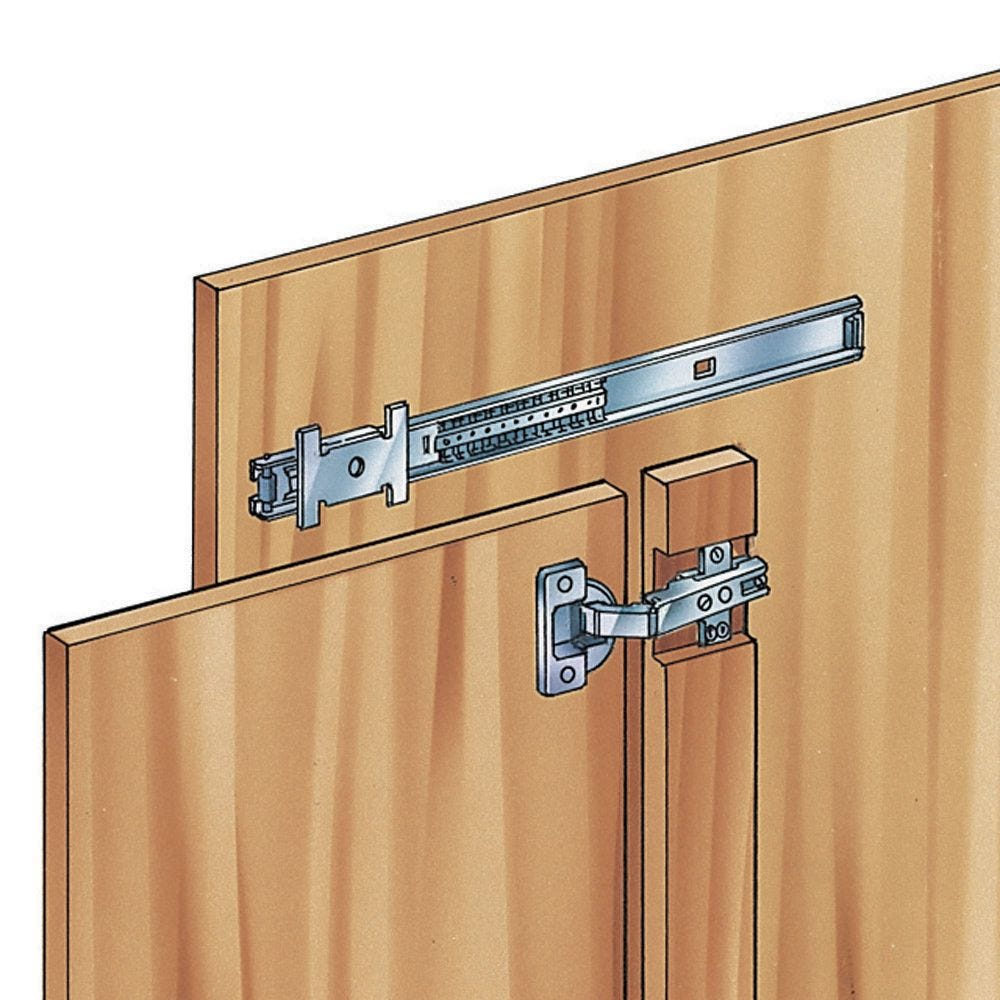

Most of the time you don t even notice it but if you hold a piece of fresh cut plywood up at eye level and peer at the edge you can see just how thin. Push door into frame until hinge pin snaps in place. Start by marking the outline of the square or rectangular hole onto the plywood sheet. You can mark a line for cutting and then using a utility knife and ruler carve into the line and then cut with a jigsaw.

How to fix a veneer door. Refer to figure 7. Raise the lower blade guard out of the way while keeping a firm grip on the saw. I do not rely on the cut person.

Before you get your plywood cut it s important to do some measuring and marking. Plywood usually come in 4 x 8 sheets which is a very unwieldy thing to cut with any tool. It could all be done with a jig saw and a guide rail for the straight edges but it would take longer and be more difficult to achieve straight lines. The system works well for both rip cuts parallel to the grain and crosscuts perpendicular to the grain.

Unless the cut is very simple like cutting the sheet in half i usually push my plywood on the cart to the drywall tools area. Engage door with hinge pin inserted into gib hinge pin plug receptacle at top of frame. Place the stick and the plywood in the center of a 48 by 96 inch sheet of plywood. Another trick is to tape the both sides of the cutting line with masking tape and then cut through the tape.

Now squeeze the trigger and slowly lower the blade into the wood. Tap the nail into the plywood to a depth of 1 8 inch. The 2x4s will be sacrificed just a bit when the blade passes over them but that won t affect the quality of the cut. Lift door align torque rod to insert into torquemaster socket at base of frame.

I get out my tape and pencil and mark exactly where i want the cut s. Lay 2x4s under the plywood perpendicular to the direction of the cut.