How To Cut And Form A Cone From Sheet Metal

Cut out your cone template from the sheet metal using your tin snips then file the edges smooth to avoid cutting yourself or someone else with the cone.

How to cut and form a cone from sheet metal. People also love these ideas. Drill a few holes through the overlapping rectangular shape. Turn the material not the scissors when cutting. Enter hole slant height up slanting edge of the cone and hole diameter and hit draw.

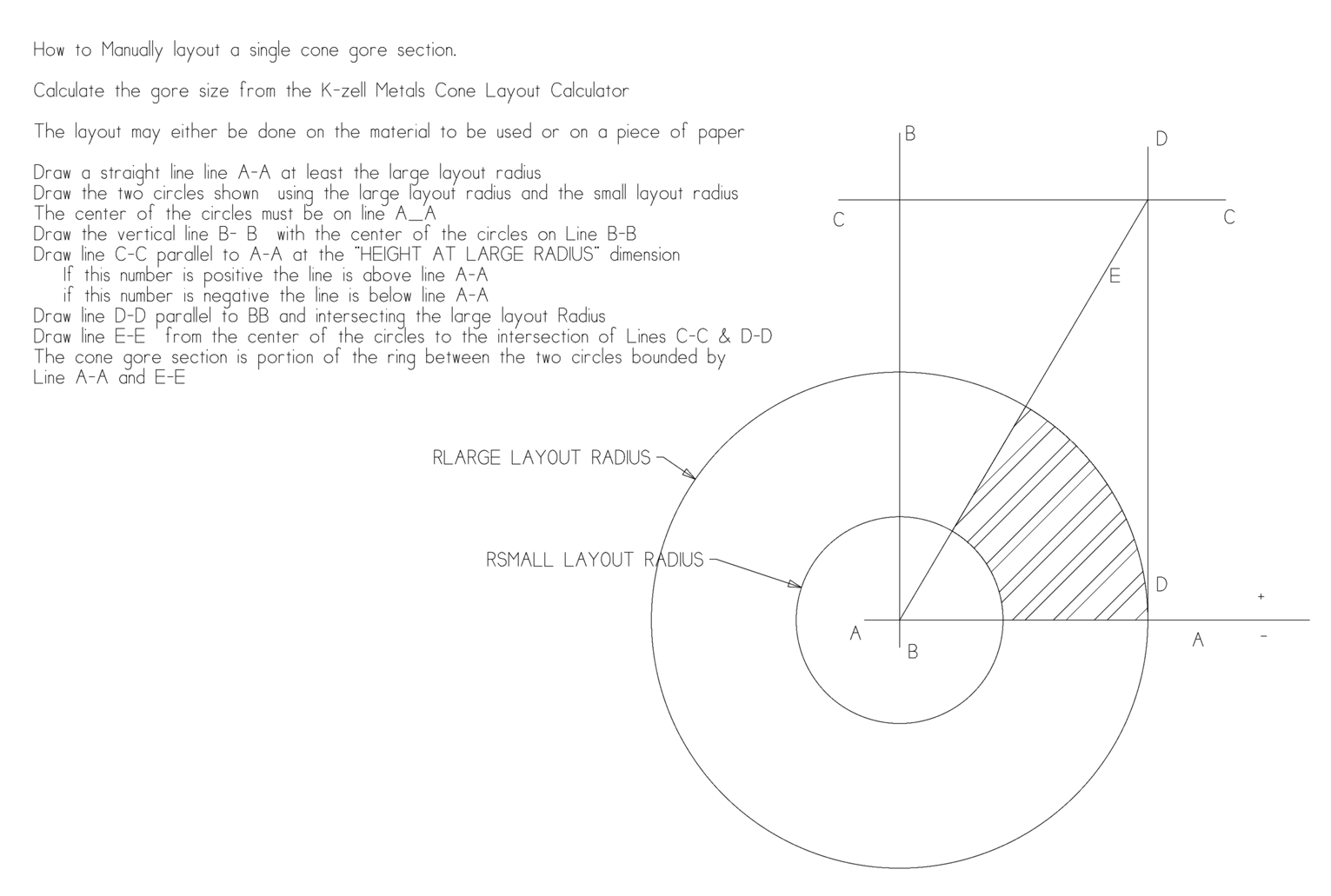

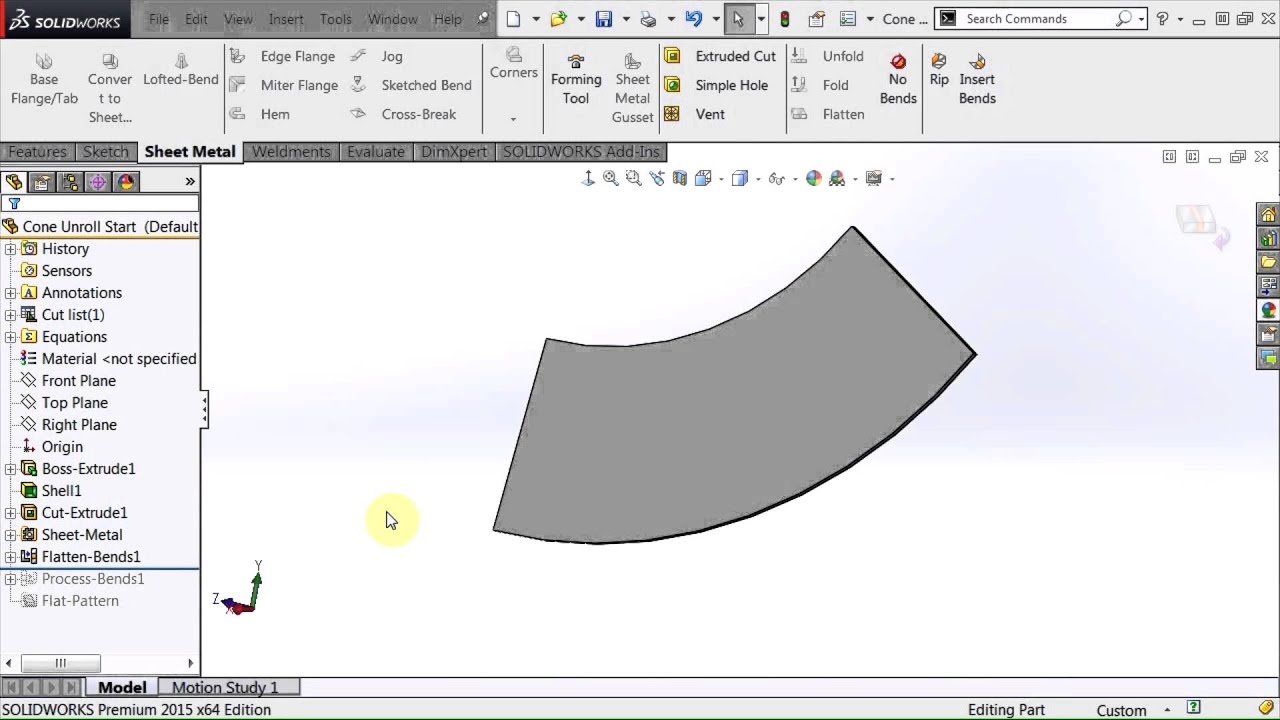

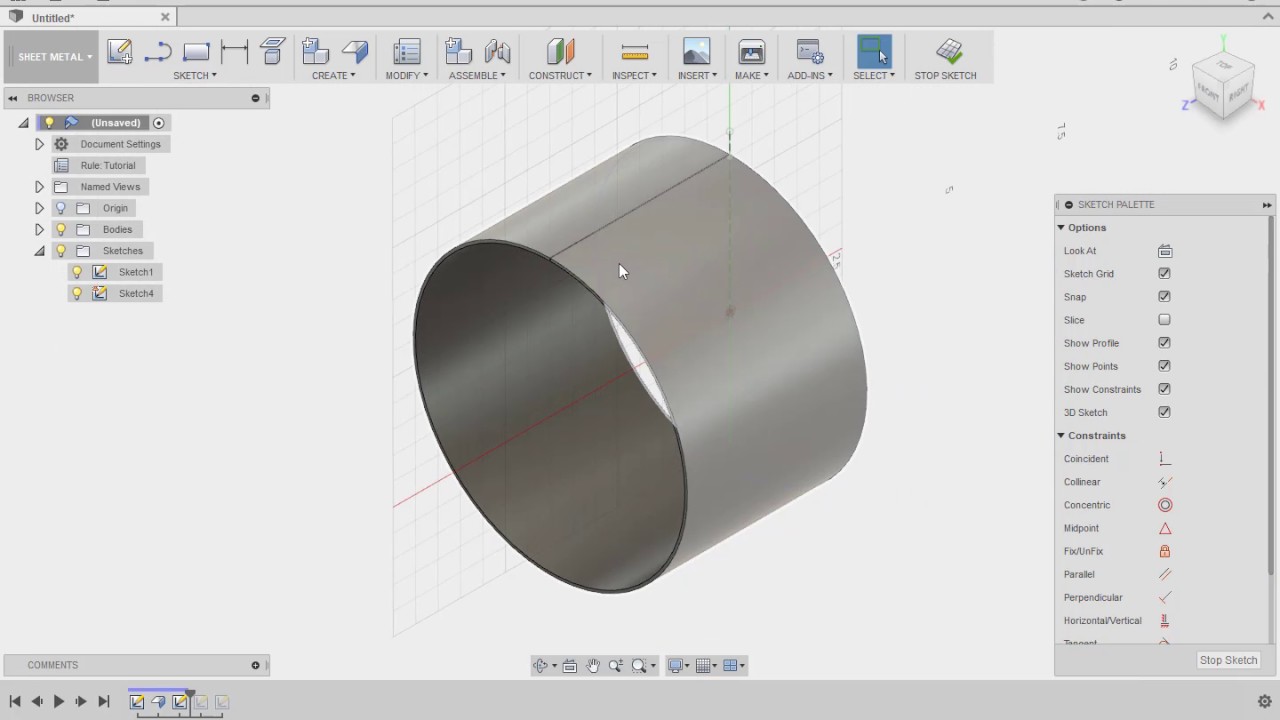

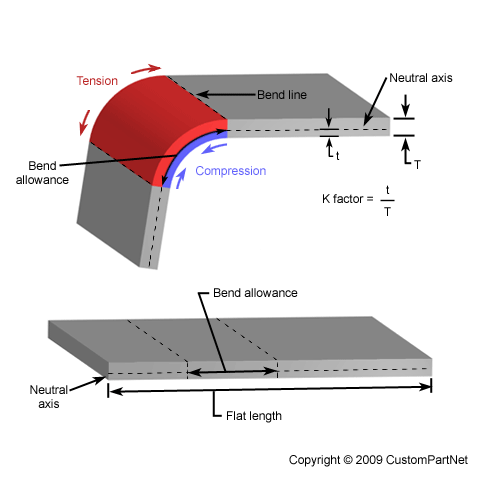

Enter top width bottom width and height of the cone see diagram and hit calculate to draw a full scale printable pattern template to mark out the cone. Cut out the cone template from your sheet metal using tin snips and file the edges smooth of any burrs of rough sections with your file. Roll the cone template into a cone shape starting at the wide end working toward the pivot point end. Sheet metal cone calculator.

Overlap one cut side onto the other. This will form the bottom edge of the cone so make cuts as neat as possible. Here is one way to make a cone from flat stock. The cone has a diameter at the top smaller than the diameter at the bottom and to accurately trace the shape onto sheet metal you need to make a template out of construction paper.

With the semicircle aligned on the straight edge of the paper only the curved part needs to be cut. View the cone instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. I used aluminum sheet coil but you could use paper or any flat material. To mark holes or lines around the cone check holes or lines and enter number of incremetns.

Metal projects welding projects metal crafts cone template sheet metal work sheet metal fabrication math formulas metal working tools metal art. As you do this you will see the circle begin to contract into a cone. Depending on how deep you want the cone stop where needed. Cut out the semicircle with scissors.

You can find cone calculators online.