How To Clean Cut Aluminum Sheet

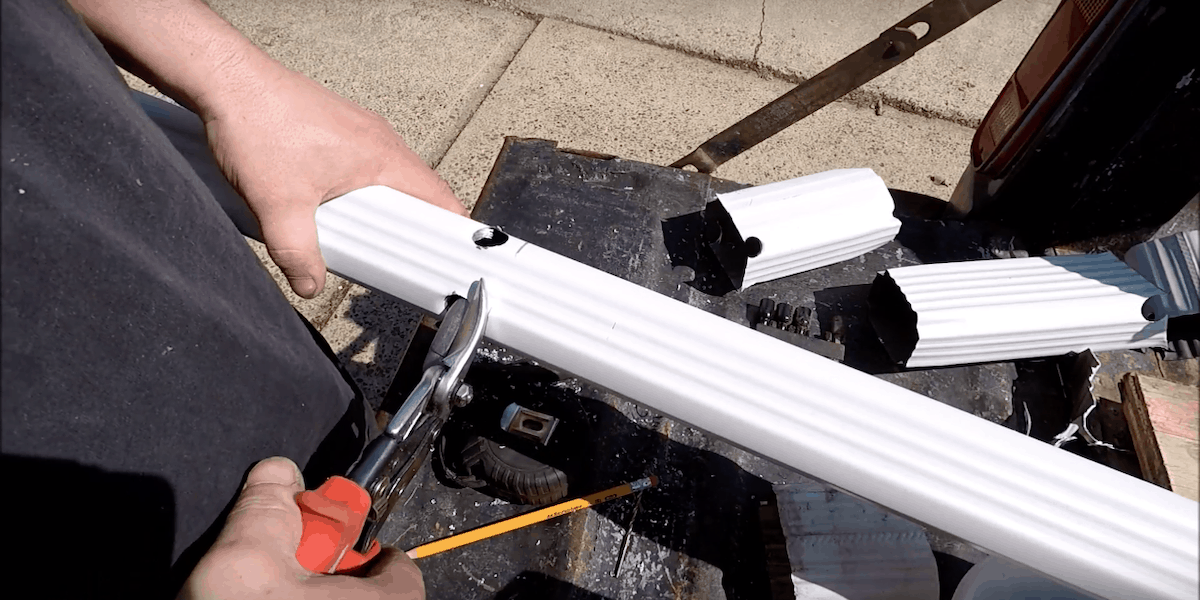

If you use metal shears to cut thin sheet metal such as duct metal it curls and can be difficult to flaten properly.

How to clean cut aluminum sheet. Wd 40 is the standard lubricant when cutting aluminum. It is stupidly fast and it leaves a nice clean cut if you can hold it. With care and patience full size sheets of aluminium can be cut using this method. Then bend the sheet back and forth a few times to snap it.

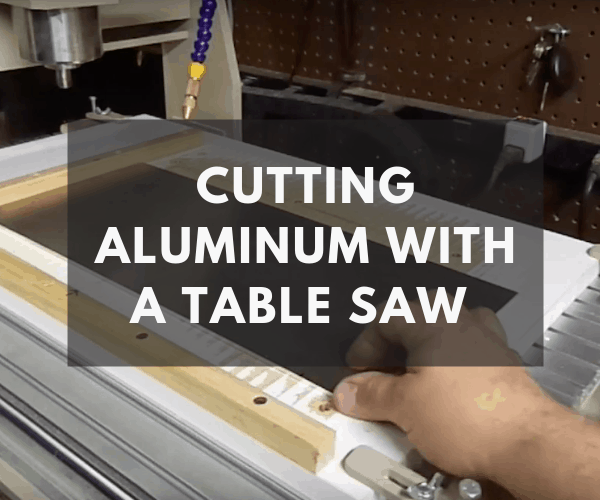

Snip the two sides. Make sure that you use coolant or a light oil like wd 40 to lubricate the cutting and prevent the chips from gumming up your blade. This can range from standard oil to saw wax. Flip the sheet over and repeat.

You can use the same trick to cut metal studs. Mark the start and stopping point of your cut with a grease pencil or some similar implement that marks on sheet metal. Either way the main problem you want to avoid is clogging the blade. To cut the sheets of metal rathe.

Harder media like silica sand tungsten carbide aluminum oxide and cold chilled copper slag will produce very clean metal. This jet of water eats away at the metal and leaving a clean smooth edge. Since you ll be cutting metal on metal you want to lubricate it to prevent sparks and slippage. Place the fracture line over the edge of a table and bend the overhang slightly downwards.

The illustrations are for a small bracket but i have cut 3 foot long pieces using this method. Soft or small blast media like soda and polystyrene beads are very slow ways to clean metal. With the aid of a ruler or yardstick draw a straight line between the two. Clamp or hold a straightedge or square along the cutting marks and score a line with the tip of a sharp utility knife blade.

This is actually one of my preferred ways to cut aluminum. Apply 5 to 6 small spurts on both the bottom and top halves of the blade. These photo steps show that it can be done using a utility knife.